20

www.BormannTools.com

6. Sailing in shallow water

6.1 Your outboard motor can be tilted (diameter 4) allow operation in shallow water.

6.2 use the machine at the lowest possible speed cruising and shallow water.

6.3 Once your boat in deeper water, your machine is adjusted to the proper position.

7. Pitch angle tilt adjustment

7.1 Longitudinal reclining lever (Fig. 3, Fig. 7) can be adjusted to the angle determined

In relation to the stern of the outboard motor. The outer side of a sloped support Positioning pins (Figure 1, Figure 9)

support in an upright position, rather than on the outside

Operation.

8. Cruise

8.1 When you work outside, at full speed, to find the key to controlling your throttle position

(Fig. 1, Fig. 4). Not necessarily the throttle to maximum, and further increase the speed may reduce fuel economy.

Try to keep your throttl

e control, at 80% or 90% of the maximum leverage effective performance.

9 Maintenance

9.1 Periodic Check for loose nuts or bolts. Regularly check the fuel line connections and inspection

Fuel and air leakage. Every eight hours after the operation, cleaning the air filter (Fig. 2, Fig. 4) With gasoline.

9.2 After each use clean the machine surface, and make partial contact with water rustproof. Do not let water

through

The exhaust port into the cylinder of the engine, the engine would have serious damage.

9.3 Always store your engine in a well-ventilated area. You should first long-term storage of your engine and the fuel

tank is completely emptied.

9.4 Water and corrosion often use grease to reduce friction and wear your outboard motor parts. Inspected once

every 10 days is recommended lubricant for every 40 to 60 days to clean up and change with a grease.

10. Replace gear oil

Warning!

For safety reasons, the propeller system is supplied without lubricant at delivery, please install angular

gear grease before operating the engine. Install the grease through the hole located at the top of the propeller neck.

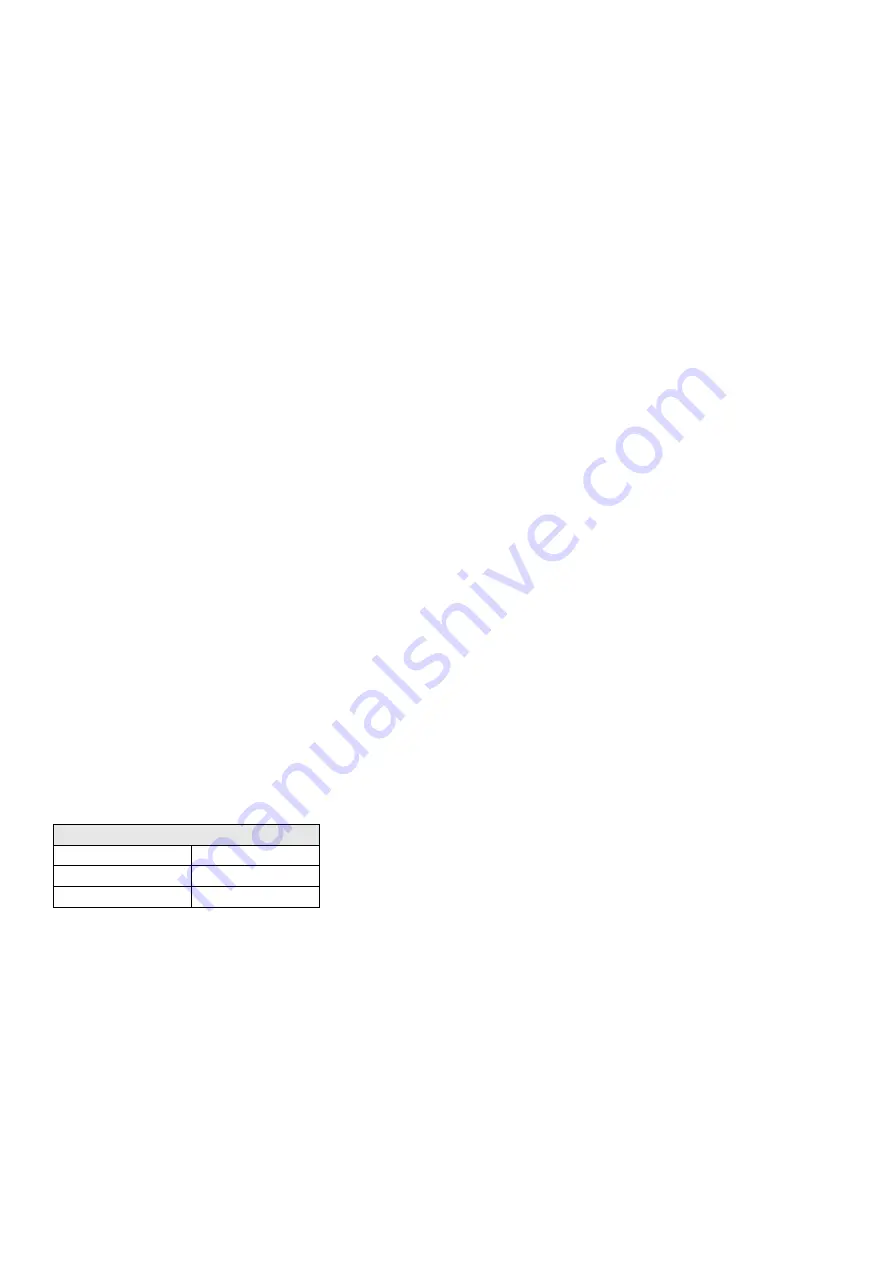

Technical Data

Engine Type:

4-Stroke

/

Petrol

Power:

1,5Hp

Propeller Diam:

1

80mm

* The manufacturer reserves the right to make minor changes to product design and technical specifications without prior notice unless these

changes significantly affect the performance and safety of the products. The parts described / illustrated in the pages of the manual that you hold

in your hands may also concern other models of the manufacturer's product line with similar features and may not be included in the product you

just acquired.

* Please note that our equipment has not been designed for use in commercial, trade or industrial applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial businesses or for equivalent purposes.

* To ensure the safety and reliability of the product and the warranty validity, all repair, inspection, repair or replacement work, including

maintenance and special adjustments, must only be carried out by technicians of the authorized service department of the manufacturer.

Engine oil

Caution!

For safety reasons the machine may not carry oil when delivered! Fill with 100ml of oil. Recommended oil type:

SAE 10W-30 API SE, SF, SG for four-stroke engines.

Summary of Contents for GM1500

Page 3: ...3 www BormannTools com ...