Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

6

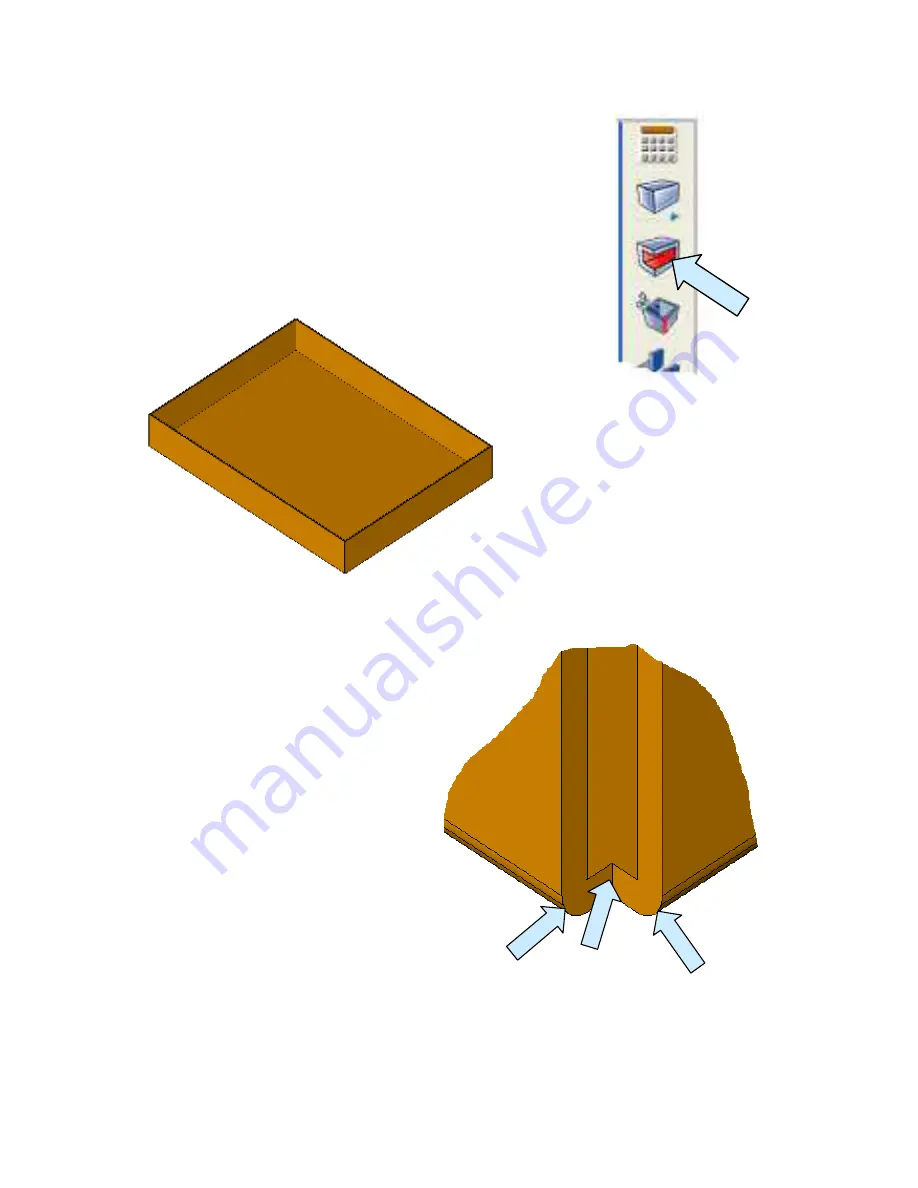

Next, click on the SHELL Icon.

When the Dialog Box appears, type “t” for the shell thickness.

Use the Select Faces to be Opened Option and click on the

OK Button.

Then, select the top surface of the block.

When the shelling operation is

completed, your part should look

like this:

Now what we have is fine as a

conceptual model of the part.

However, it does not represent a sheet

metal fabricated part for two reasons.

First, the bends at the bottom edges are

not sheet metal bends and second, the

corners are closed as though it were

molded from a piece of plastic.

I’ve illustrated what we want to

achieve in the enlarged view to the

right. (Note: In actual practice we use

a much smaller corner rip. I’ve made

this one large so you can see what is

going on.)