SKY PRO 1800 FORCED CIRCULATION MANUAL

C

C

37

LOADING

- Before loading the operation system you must ensure that solar collectors only are at low

temperature. Anywhere the solar collectors must remain covered at least 5 hours before to loading.

- The charging system must be meticulously carried out by following the instructions on pages

14:16 of this manual. We also recommend the use of the pump loading facility provided by us

(cod.101010045). Proper paper loading allows the complete elimination of air in the solar circuit, and

working properly.

- The optimal pressure of the plant we suggest is 3/3.5 bar for heating station and at least 2/2, 5 bars

to the collectors when system is switch-off.

SIZING

- Before switching on the solar system make sure that the sizing and adjustment of individual

components (panels, expansion tank, glycol, flow control, pump station) are consistent as indicated

on page. 9 of this manual.

- Make sure that size of diameter of the copper piping components of the solar circuit be conform to

what we have indicated on page. 18 of this manual. If unsure about this persist you should contact

your Kloben or our authorized personnel of technical department.

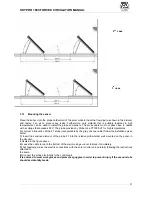

WEATHERPROOF BEHAVIOUR AND ACTIONS DUE TO MECHANICAL LOAD BY WIND AND SNOW

The solar collectors of SKY PRO family are conform to DIN EN 12975-1:2006-06 and DIN EN 12975-1 :

2006-06 and we are granted the license to use the marks of Solarkeymark DINCERTCO with registration

No.: 011-7S1476 R. The system as whole for any dwelling falls under building regulations Part L 2008, SEAI.

Minimum recommended insulation thickness for the solar piping is at least the external diameter of the pipes.

External pipe runs should be insulated suitably to protect against weather etc. A pre- insulated cylinder is

recommended, with a minimum of 50mm insulation thickness. See also section 3.6 of this manual.

MATERIALS

•

All piping components of the solar circuit should preferably copper made. It 's absolutely discouraged the

use of other materials such as galvanized steel, plastic, plywood and related products. In the case you use

materials other than copper, it will be impossible to guarantee the proper functioning of the system.

•

Using tubes stainless steel made or black steel ones make attention to the type of joints or fittings

you need. The joints must be able to withstand long periods with the presence of gas under pressure

with temperatures higher than 250 ° C.

•

All joints should be made welding or tightening fittings for copper. Any other use of materials could affect

the security of joints over time.

•

In order to avoid problems of joints due to hydraulic circuit solar thermal stresses, always check the

distance between the solar collectors with respect to cylinder. In any case, should always make the junction

with Teflon for high temperatures.

•

The pipe insulation must be made with copper tubing for high temperature solar Kloben type.

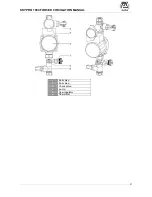

VERIFY - CHECKS PROCEDURE

•

Verify that the pre-charge pressure vessel conforms to the project

•

Check the correct connection of the solar control probes.

•

Verify that the setting’s parameters of the solar controller complies with all requirements in the design

phase.

•

Verify the correct insertion of the probe and make sure that the collectors cannot be damaged or

subsequent movements.

Notes:The solar collectors cannot be exposed to sunlight for long periods without being loaded (max

10 days)

Summary of Contents for SKY PRO 10 CPC 58

Page 1: ...TECHNICAL MANUAL SOLAR COLLECTORS SKY PRO 1800 ...

Page 2: ......

Page 47: ...SKY PRO 1800 FORCED CIRCULATION MANUAL C C 47 ...

Page 49: ......