ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

21 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

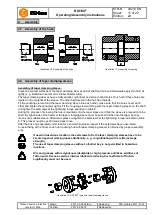

Table 12:

Size

Limits of wear (friction)

Size

Limits of wear (friction)

X

max.

[mm]

X

max.

[mm]

9

2

65

5

14

2

75

6

19

3

90

8

24

3

100

9

28

3

110

9

38

3

125

10

42

4

140

12

48

4

160

14

55

5

180

14

In the explosion groups

IIA

,

IIB

and

IIC

the following materials may be combined:

EN-GJL-250

(GG 25)

EN-GJS-400-15

(GGG 40)

Steel

Stainless steel

Semi-finished products of aluminium with a magnesium share of up to 7.5°% and a yield point of

R

p0.2

≥ 250 N/mm

2

are permitted for the use in hazardous locations.

Aluminium diecast

is generally excluded for hazardous locations.

Couplings for the use in hazardous locations are marked on at least one component completely and on the

remaining components by an

label on the outside diameter of the hub or on the front side each for the

operating conditions permitted. The flexible spider or DZ element is excluded. For reason of limited space only the

symbol

is stamped up to size 19.

Short labelling:

(standard)

II 2GD c IIC T X/I M2 c X

Complete labelling:

(valid for T-PUR

®

only)

II 2G c IIC T6, T5, T4 resp. T3 - 50 °C

T

a

+ 65 °C, + 80 °C,

+ 115 °C resp. + 120 °C

II 2D c T 140 °C/I M2 c - 50 °C

T

a

+ 120 °C

Complete labelling:

(valid for PUR only)

II 2G c IIC T6, T5 resp. T4 - 30 °C

T

a

+ 65 °C, + 80 °C resp.

+ 90 °C

II 2D c T 110 °C/I M2 c - 30 °C

T

a

+ 90 °C

The labelling with explosion group llC includes the explosion groups llA and llB.

If the symbol

was stamped in addition to

, the coupling component was supplied unbored or pilot bored by

KTR.

10

Enclosure A

Advice and instructions regarding the use in

hazardous locations

10.3 Standard values of wear

10.4 Permissible coupling materials in

hazardous locations

10.5

marking of coupling for hazardous locations