6 Commissioning/Start-up/Shutdown

30 of 60

Sewabloc

6.2.2 Frequency of starts

To prevent high temperature increases in the motor and excessive loads on the

pump, motor, seals and bearings, the frequency of starts shall not exceed the

following number of start-ups per hour.

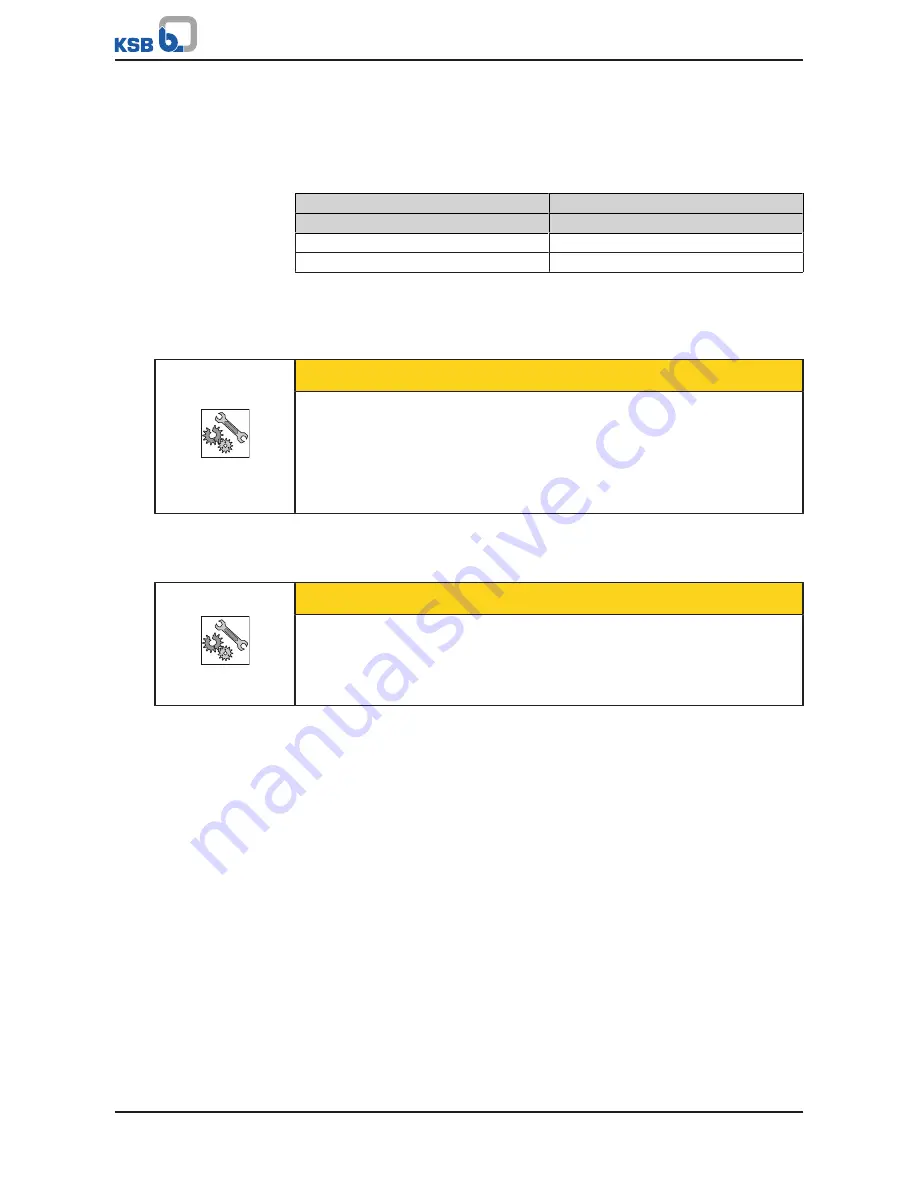

Table 14:

Frequency of starts

Rated motor power

Maximum frequency of starts

[kW]

[Start-ups/hour]

≤ 11

25

12 - 37

20

6.2.3 Fluid handled

6.2.3.1 Temperature of the fluid handled

CAUTION

Impermissibly high temperature of fluid handled

Damage to the pump!

▷

Prolonged operation against a closed shut-off element is not permitted

(heating up of the fluid).

▷

Observe the temperature limits in the data sheet and in the section on

operating limits. (

ð

Section 6.2, Page 28)

6.2.3.2 Density of the fluid handled

The pump input power changes in proportion to the density of the fluid handled.

CAUTION

Impermissibly high density of the fluid handled

Motor overload!

▷

Observe the information about fluid density in the data sheet.

▷

Make sure the motor has sufficient power reserves.

6.2.3.3 Abrasive fluids

Do not exceed the maximum permissible solids content specified in the data sheet.

When the pump handles fluids containing abrasive substances, increased wear of the

hydraulic system and the shaft seal are to be expected. In this case, halve the intervals

commonly recommended for servicing and maintenance.

6.3 Shutdown/storage/preservation

Storing a new pump set

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for pump (set) storage:

▪

Store the pump (set) in a dry and protected location.

▪

If properly stored indoors, the pump set is protected for a maximum of 12

months.

New pumps are supplied by our factory duly prepared for storage.

▪

Rotate the shaft of the pump by hand once a month.

Summary of Contents for Sewabloc Series

Page 59: ......