MEGACHEM

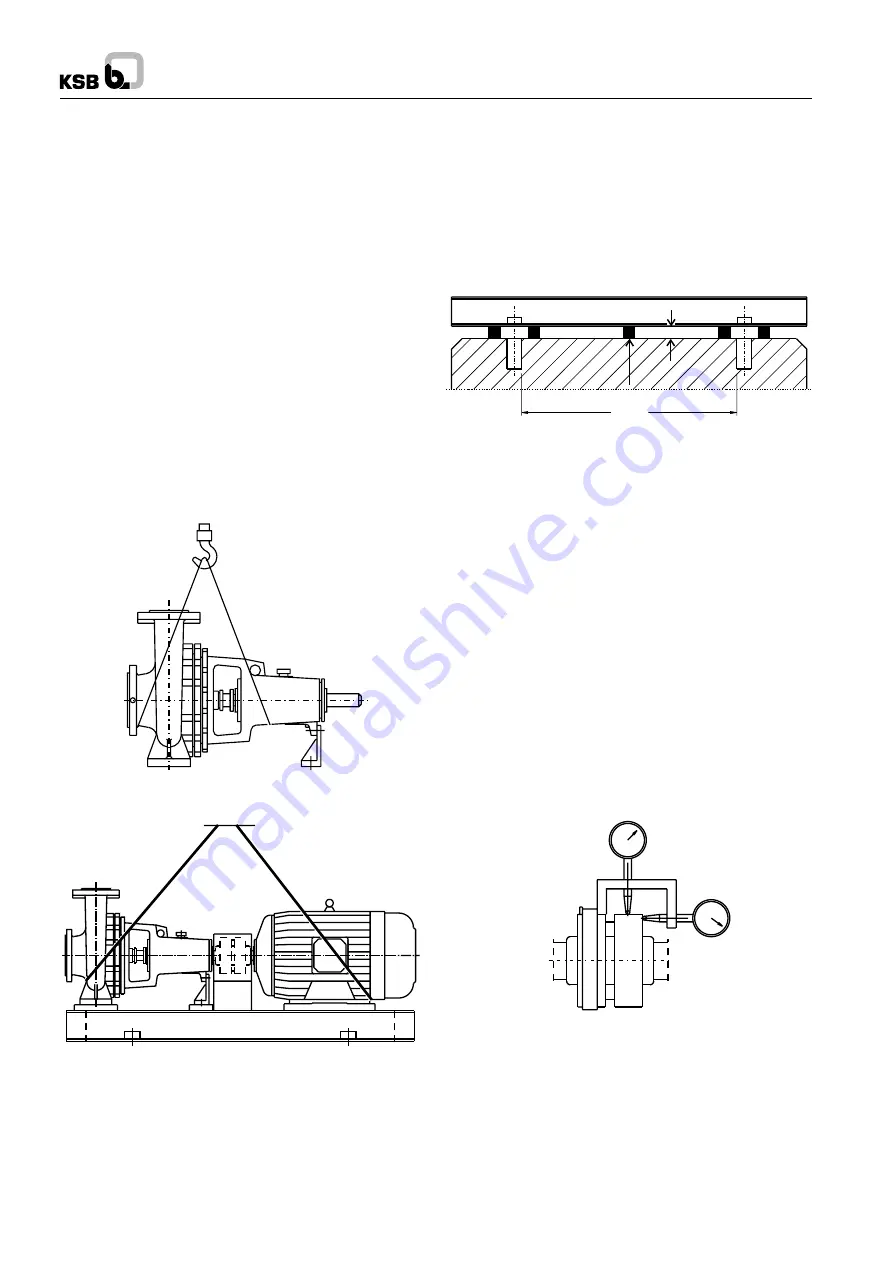

>800

min. 50 mm

1

1

General

Your centrifugal pumps will only give you completely

trouble free and satisfactory service on condition that it is

installed with due care and properly maintained. It is

absolutely essential that the instructions contained in this

manual be strictly observed and that the pumps are not

operated under conditions which differ from those specified

under our 'Operating Conditions' This operating instruction

manual does not take any account of any safety regulations

which may apply to the installation site, and the site engineer

& the site operator is responsible for notifying our erection

staff of any such regulations and seeing that they are complied

with.

The type series, pump sizes, main operating data and the

works order number are all stamped on the name plate affixed

to the pump. Please make sure to quote this information every

time you write to us in respect of queries, repeat orders and

more particularly when ordering spare parts.

1.1

Handling

When handling the complete pumpset or bare pump attach

ropes to the pump and motor as shown (not through the motor

eyebolt).

Fig. no.1 : Bare Pump

Fig no.2 : Pump & motor on a common baseframe

2

Installation (on site)

2.1

Foundation

Make sure the concrete foundation has set before mounting

the pumpset. The surface of the foundation must be completely

horizontal and perfectly flat.

2.2

Mounting

Position the pumpset on the foundation and align using a

precision spirit level on the discharge nozzle. Ensure that

the gap between the two coupling halves is as given on the

general arrangement drawing. Always fit shims to the left and

right of the anchor bolts, between the baseplate / foundation

frame and the foundation. If the shims are more than 800 mm

apart, position extra shims equidistant between them. All shims

must seat perfectly flush with the baseplate/frame.

Fig no.3 : Fitting shims

Uniformly tighten up securing means. Baseplate have to be

grouted with non-shrinking mortar up to the upper edge of the

frame after having been fixed in position.

2.3

Aligning pump / motor

After the baseplate has been fixed in position carefully check

the coupling and, if necessary, realign the pumpset (on the

motor). Prior to checking the alignment and / or aligning,

loosen supporting foot (183) and tighten again without

transmitting any strain. The coupling must also be checked

and the pumpset realigned even if the pump and motor are

supplied ready mounted on a common baseplate.

The pumpset to be aligned radially and axially within 0.04 mm

by installing dial indicators and without pipe connection. The

gap between the two coupling halves must be the same at all

points (minimum 3 points) on the circumference; this can be

measured using calipers or a filler gauge.

The alignment should be carried with & without pipe

connections and should be within limits. For liquids handling

more than 105

0

C

cold alignment & hot alignment should be

carried out on pumpset.

Fig. no. 4 : Aligning a coupling

2.4

Connecting the piping

Never use the pump itself as an anchorage for the piping.

Suction lift lines should be laid with a rising slope towards the

pump and suction head line with a downward slope towards

the pump (fig. 5b, 5c)

The pipelines should be anchored in close proximity to the

pump and should be connected to the latter without transmitting

any stress or strain, nor should weight of the piping be loaded