4 Transport/Temporary Storage/Disposal

13 of 36

BOA-Control/ BOA‑Control IMS

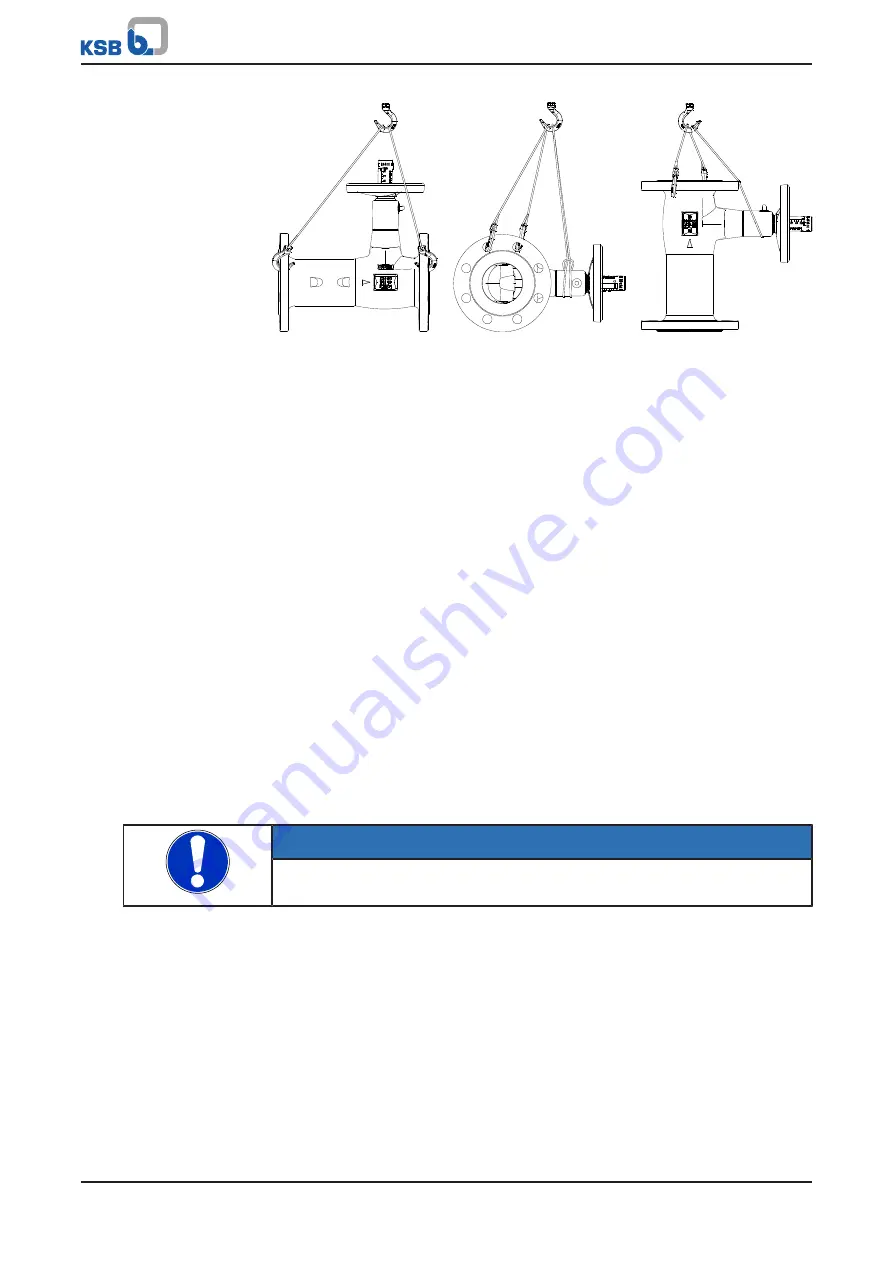

Fig. 1:

Transporting the valve

4.3 Storage/preservation

If properly stored indoors, the equipment is protected for a maximum of 12 months.

This allows commissioning to take place some time after delivery. We recommend

that the following measures be taken:

▪

Store the valve in a dust-free and vibration-free, frost-proof room where the

atmospheric humidity is as constant as possible (use suitable caps or film for

protection).

▪

Protect EPDM-encapsulated valve discs from sunlight or UV light from other

sources. Observe the DIN 7716 standard for the storage of elastomers.

▪

Close the valve using little force and store in the closed position.

▪

Protect the valve from contact with solvents, lubricants, fuels or other chemicals.

4.4 Return to supplier

1. Drain the valve as described in the manual.

2. Flush and clean the valve, particularly if it has been used for handling noxious,

explosive, hot or other hazardous fluids.

3. If the valve has handled fluids whose residues could lead to corrosion damage in

the presence of atmospheric humidity or could ignite upon contact with oxygen

also neutralise the valve and blow through with anhydrous inert gas to ensure

drying.

4. When returning valves used for handling Fluids in Group 1 always complete and

enclose a certificate of decontamination.

Indicate any safety measures and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: