Page 3

Copyright © 2009 GEBEL Aquasafe. • All Rights Reserved • May 2010 • Pub. No. MAN 200

FIBREGLASS WETWELL INSTALLATION

!

!

BEFORE YOU BEGIN

• Read, understand and follow these instructions.

• Barricade the work area.

• Review and prepare to complete the installation checklist as

the installation progresses.

If you have questions on other wetwell installation details, call

Technical Support at 02 4722 9696

A. HANDLING AND PREPARATION

WARNING

Do not stand on or under wetwell while it is being lifted. This

could result in personal injury or death.

• Do not drop or impact the wetwell.

• Wetwells should be stored horizontally and chocked, using

only appropriate materials such as sandbags, tires, or other soft

or pliable materials.

• Upon wetwell delivery and when lifting wetwell, visually

inspect entire exterior surface of the wetwell for shipping or

handling damage.

• If the wetwell must be moved by rolling, ensure that ground

to be traversed is smooth and free of rocks, debris, or other

hard objects.

• Do not roll or set the wetwell on any pipe stubout, acces

-

sory or appurtenance installed on the wetwell.

• The contractor is responsible for rigging, unloading and se

-

curing the wetwell.

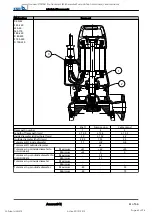

• When lifting the wetwell in the horizontal position, use two

slings with a spreader bar.

• Use a minimum of two lift lugs when pivoting the wetwell

from horizontal to vertical.

• Utilize all lift lugs provided at the wetwell top for vertical

lifting.

• Only a pliable strap or rope should contact the wetwell, do

not use chains, steel cables or hard metallic slings.

B. SITE PREPARATION

Dimensions of the excavation should be wide enough to pro

-

vide sufficient working room around the wetwell.

Minimum anti floatation ring and ballast dimensions are speci

-

fied in (Table 1, page 7)

Anti floatation ring and ballast designs in (Table 1, page 7) meet

Australian Standard Code S3600A.

(Dead load resisting floatation have a factor of safety of

0.9 applied.)

!

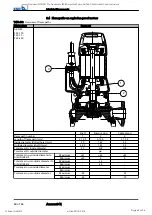

C. ANTI FLOTATION BALLAST FRP

WETWELLS

WARNING

Collapsing excavation walls can cause injury or death. Do not

enter the wetwell excavation unless necessary and in compliance

with OHS regulations. Follow OHS guidelines for excavations.

WETWELLS

• Lower Wetwell onto Compacted Base then place Wet con

-

crete around the Unit covers 2 x Ribs plus meets the Ballast

Quantity in (Table 1 and figure 1, page 7.)

Cold concrete joints are not allowed. Fibreglass solid bot

-

tom wetwells with external reinforcing ribs must be installed

in a continuous and monolithic concrete pour. Concrete must

extend 75mm above the second rib from the wetwell bottom,

and around the entire circumference of the wetwell. (Refer to

figure 1, page 7)

• Concrete slab must fill all gaps and voids in and around the

external tank reinforcing ribs.

• It may be necessary to add ballast (water) inside the wetwell

to counteract buoyancy until the concrete is cured.

ANTI FLOATATION RING CONCRETE SLAB

Use minimum 20 mpa concrete for anti floatation and ballast

Final concrete depth, size, thickness and reinforcements

shall meet the minimum requirements in these instructions

and applicable tables. Anti floatation ring should extend a

minimum of (refer to table 1, page 7) in all directions from the

wetwell outer diameter.

CAUTION

Voids in the concrete slab around external structural anchors will

result in product damage and environmental contamination.

Goodnal STP ST041 Pre Treatment (KSB Amenities Pump Station OM Manual) Vendor Manual

Q-Pulse Id VM372

Active 29/10/2013

Page 71 of 94