Sanding

Place the entire sanding surface of the eccentric san-

der onto the piece to be sanded. Only then should the

sander be turned on. Apply only light pressure when

switching on the device.

The pressure of the eccentric sander on the workpiece and

the grain of the selected sanding disc influence the re-

moval rate and the surface appearance.

The removal rate is determined by the rotational speed of

the sanding plate.

Rough finish

Apply only light pressure to the sander. The rotating sand-

ing plate will remove more surface from the workpiece.

Fine finish

When more pressure is applied to the eccentric sander,

the sanding plate will rotate more slowly but the eccentric

motion will remain and the finish will be like that of an

oscillating type sander.

Attention!

The eccentric sander must be used for dry work only!

The overlaid sanding motion rotating/oscillating produces

similarly good results to wet sanding.

Selecting the right sanding plate

The selected sanding plate (harder/softer) depends on the

material being sanded (see table of application examples).

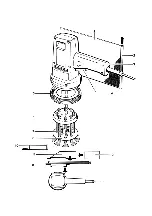

Fitting the sanding plate

Caution!

Disconnect the mains plug!

Attach sanding plate (6) to the tool and screw on with the

3 fixing screws (7).

Replace damaged sanding plates immediately! Never

start the tool when there is no sanding plate attached!

Mounting the sanding tools

Use only the original KRESS sanding tools with the self-

adhesive Velcro fastener.

Caution!

Disconnect the mains plug!

Clean the sanding plate if it is dirty!

The sanding tools (8) are simply pressed onto the sanding

plate (6). The holes in the sanding disc must correspond to

the holes in the sanding plate. Only then can malfunction-

free suction of sanding dust be guaranteed.

Care and maintenance

Every tool becomes fouled with dust and dirt when work-

ing with wood. A little care is therefore indispensible. It is

especially important to always keep the holes for cooling

the motor free of dust and dirt.

Blow out the motor with pressurized air regularly (at shorter

intervals when in heavy use). All moving parts are lubri-

cated sufficiently with grease before leaving the factory.

The eccentric sander is practically maintenance-free.

Replacing carbon brushes

Our service personnel will do this and all other servicing

work fast and professionally.

Power cable

Damaged power cables may not be used. They must be

replaced immediately by a qualified electrician.

Attention!

Pull mains plug prior to starting any type of mainten-

ance job!

Important!

Do not restart the machine until all parts are screwed

together properly!

Noise/vibration information

Measurement values determined in accordance with

EN 50144.

Acoustic pressure level:

69

+3

dB (A)

Acoustic power level:

82

+3

dB (A)

Workplace emission value:

72

+3

dB (A)

Noise protection measures are necessary for the operator.

The weighted acceleration is typically smaller than 2.5 m/s

2

.

Subject to changes serving engineering progress without

prior notice.

Special accessories

Sanding sheets, grain: 40/80/120/240/400

Steel wool, grain 100/280

Soft sanding plate

Examples of application

Sanding

Application

Grade

plate

Grinding damaged

bodywork

80–120

soft

Polyester fillers rough fin.

80–120

soft

Prime filler surfaces

240–400

soft

Sanding off old paint

40–80

hard

Surface sanding on paint

120–240

hard

medium mat

Sanding paint off concrete

40

hard

Sanding natural finish wood

120

hard

Surface sanding wood

medium mat

hard

to pores (accentuating grain)

Grinding off anti-fouling

and ships hulls

40–120

soft

Rough sanding fibre glass

reinforced plastics

40–80

hard

Fine sanding fibre glass

reinforced plastics

240–400

soft

Derusting steel

rough and

hard

medium mat

Polishing up vehicle paint

polish pad

hard

Polish high gloss

polish hood

hard/soft

Hexe115_12510_01.qxd 16.12.2003 18:19 Uhr Seite 7

Summary of Contents for CPS 6125-1

Page 2: ...Hexe115_12510_01 qxd 16 12 2003 18 19 Uhr Seite 2 ...

Page 3: ......