RT10116

Version 20070701

· Woodworking machines are dangerous, and can cause personal injury if not

used

properly.

· Read safety instructions and operating instructions for your machine completely,

before using products. Using this system before understanding its safe and

proper use could result in serious injury to the operator.

· Failure to follow these rules may result in serious personal injury.

· For your own safety, read instruction manual before operating the tool. Learn the

tools application and limitations as well as the specifi c hazards distinctive to it.

· Keep all guards and safety devices in proper place while using these products.

· Always wear safety glasses.

· Keep hands well away from the rotating bit when operating machine.

· Avoid akward hand positions, where a sudden slip could cause contact with the

rotating bit.

· This system was designed for certain applications only. Kreg strongly recommends

that this system NOT be modifi ed and/or used for any application other than

for which it was designed. If you have any questions relative to its application,

DO NOT use the tool until you have written, phoned, or e-mailed Kreg Tool and

have been advised accordingly.

· Be aware of kickbacks. Kickbacks occur when the workpiece binds-up while being

routed, causing it to twist, jump, and possibly become airborne. To avoid kick

backs (and potential injury) always use sharp bits, keep the machine aligned and

maintained properly, and adequately secure/support the workpiece.

· Turn machine off before adjusting. Never adjust the fence, plate level, reducing rings,

or any other part of the tool while the machine is running.

· Wait for the machine to stop. Make sure the router comes to a complete stop before

adjusting the workpiece or workpiece-angle.

· Ground electric machines. If your machine is equipped with a three-prong plug, it

should be plugged into a three-hole electrical receptacle only. If the proper

outlet is not available, have one installed by a qualifi ed electrician before use.

Never remove the third prong, and never modify the provided plug in any way.

· Don’t operate in a dangerous or unclean environment. Don’t use power tools in

damp or wet locations, or expose them to rain. Keep work area well-lit,

un-cluttered, and clean.

· Keep children and visitors away. All children and visitors should be kept a safe distance

from the work area, and should not operate the tool under any condition.

· Make your workshop “child-proof”. Use padlocks, master switches, or any other means

necessary to make your work area safe for children.

· Use the right tool. Never ‘force’ the tool to do work for which it was not intended. If used

properly, the tool will produce better results in less time, under safer conditions.

· Wear proper apparel. No loose clothing, gloves, neckties, rings, bracelets, or any other

jewelry that could possibly get caught in moving parts. Non-slip footwear is highly

recommended, as is protective hair covering. Remember to always use safety glasses,

specifi cally designed as safety wear.

· Secure the workpiece. Use clamps or a vise to hold work when it is practical and safe.

Using the proper tool may allow you to free both hands for tool operation. Also, be sure

to never overreach.

· Secure your tools. In the event of the machine tipping or sliding, it is always

recommended to secure your tools to the machine during use.

· Keep the proper footing and balance. Ensure that you are in no danger of slipping or

sliding once you turn the machine on. Once again, non-slip footwear is highly

recommended.

· Maintain tools in top condition. Keep tools sharp, clean, and properly maintained for the

highest quality and safest performance. Remember to properly follow all lubrication and

accessory maintenance practices, as detailed in this Instruction Manual.

· Disconnect tool before servicing. When changing accessories such as bits, clamps, etc.,

making any sort of physical assessment of the tool, or when motor is being mounted/

connected, remember to disconnect the machine from its power source. This will reduce

the possibility of accidentally engaging the machine.

· Check for damaged parts. Before use of the tool, a careful assessment of all guards and

other parts should be made to ensure that it will operate properly, and perform as

intended. Check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced as soon as possible,

preceding any additional use. Do not use the tool if you are not qualifi ed to make these

sorts of assessments.

· Never leave a running machine unattended. Always turn the machine’s power “OFF”

after operation. Do not leave the tool until it comes to a complete stop.

· Drugs, alcohol, medication warning. Do not operate tool while under the infl uence of

drugs, alcohol, or any medications.

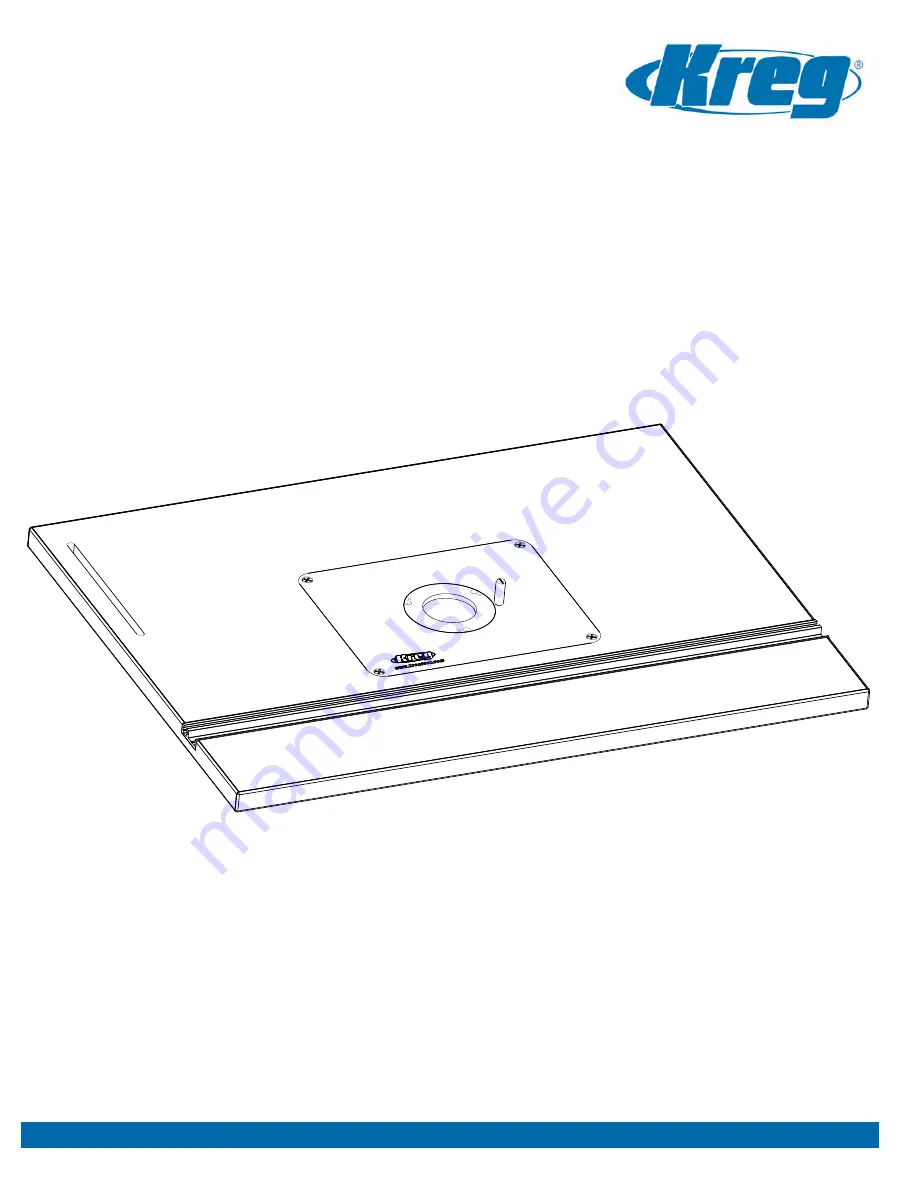

Router Table Top

Precision

ASSEMBLY INSTRUCTIONS

Item# PRS1020

Other Precision Routing Products

Safety Guidelines

7.

(

24” x 32”

)

Tools Required:

• 5/64” Allen Wrench

• Phillips Head Screwdriver

• Flat Head Screwdriver

• 6” #2 Square Driver

• 1/8” Allen Wrench (Included)

• 3” #2 Square Driver (Included)

www.kregtool.com • 800.447.8638

This unique featherboard can be quickly and easily connected to almost any

miter slot or t-slot without the need for additional hardware. It features a durable

plastic composite body which ensures optimum workpiece pressure.

True-FLEX

True-FLEX

Featherboard

Featherboard

TM

Item# PRS3010

Taking cues from high-end table saw rip fences, this groundbreaking router

fence provides an entirely new way to work. It’ll make every project you

start faster, easier, and far more precise than ever before.

Precision Router Table Fence

Precision Router Table Fence

Item# PRS1010

www.kregtool.com • 800.447.8638

Come meet the entire family of Precision Routing Products

Come meet the entire family of Precision Routing Products

at www.kregtool.com

at www.kregtool.com