Page 13

For technical questions, please call 1-800-444-3353.

Item 69584

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

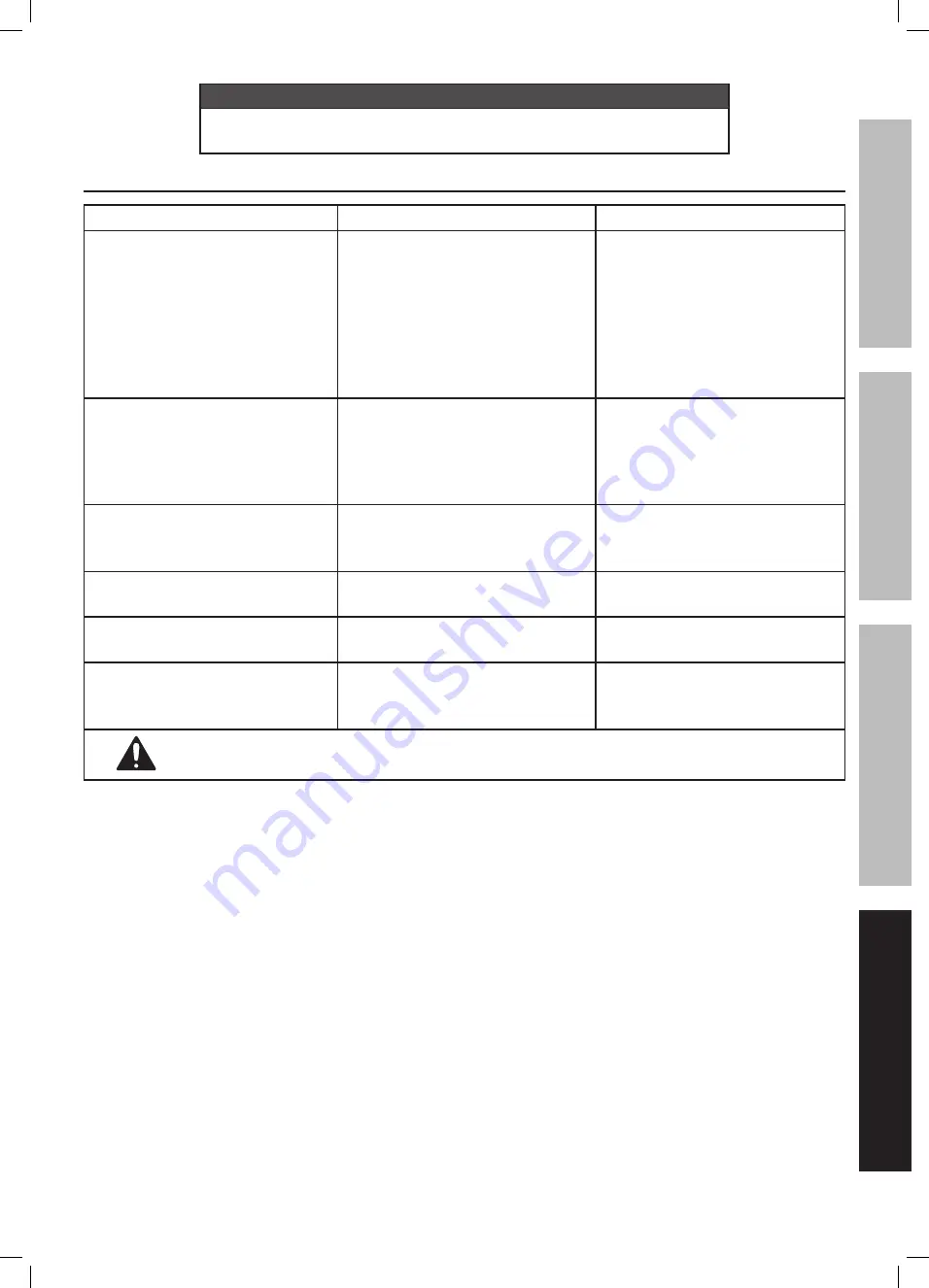

Troubleshooting

Problem

Possible Causes

Likely Solutions

Tool will not start.

1. Cord not connected.

2. No power at outlet.

3. Internal damage or wear.

(Switch, for example.)

1. Check that cord is plugged in.

2. Check power at outlet.

If outlet is unpowered, turn off

tool and check circuit breaker.

If breaker is tripped, make sure

circuit is right capacity for tool

and circuit has no other loads.

3. Have technician service tool.

Overheating.

Motor being strained by long or

small diameter extension cord.

Eliminate use of extension cord.

If an extension cord is needed,

use one with the proper

diameter for its length and load.

See

Extension Cords

in

Grounding

section on page 5.

Sputtering Spray

1. Low paint level.

2. Cup tipped.

3. Loose/damaged fluid tip/seat.

1. Refill.

2. Hold upright.

3. Adjust or replace fluid tip.

Will Not Spray

1. Control Knob not open enough.

2. Fluid too thick.

1. Open Control Knob.

2. Thin fluid.

Overspray

(Paint drifting to unintended objects.)

1. Improper application speed.

2. Improper distance from workpiece.

1. Move moderately and parallel.

2. Adjust distance.

Fluid Tip Leakage

1. Dirty tip.

2. Broken fluid needle spring.

3. Worn or damaged tip.

1. Clean tip.

2. Replace fluid needle spring.

3. Replace tip and/or needle.

Follow all safety precautions whenever diagnosing or servicing the tool.

Unplug tool before service.

SAFETY

OPERA

TION

MAINTENANCE

SETUP

Summary of Contents for 69584

Page 1: ......