Instruction manual

www.

kraftool.hk

www.

kraftool.hk

Electric spray gun

|

|

10

11

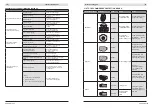

Protection means

Picture

Code

Name

Notes

Respirator

11127-Н2

Respirator with 1

replaceable filter

A1 filter (from organic

gases and vapors)

11129-Н3

Respirator with 2

replaceable filters

A1 filter (from organic

gases and vapors)

11162

Anti-aerosol

respirator , conic

shape, with a valve

FFP2 protection class

(protection

against

fine aerosols)

Goggles

110235

Closed type googles

Acetate chemical

resistant lens. Protection

classes 3, 4, 5(see on

the product)

110237

Polycarbonate lens.

Protection classes 3, 4,

5(see on the product)

110242

PVC lens.

Protection classes

3, 4, 5(see on the

product)

110244

Polycarbonate lens.

Protection class 3, 4, 5

(see on the product)

Gloves

112

7

0-хх

latex gloves

Protection against

detergents, alcohol-

containing liquids, oils

and fats

112

75

-хх

working gloves

coated with

latex

L

IST

OF

R

ECOMMENDED

P

ROTECTION

M

EANS

POSSIBLE FAULTS AND ELIMINATION METHODS

Fault

Possible cause

Trouble shooting

The product does not switch on

No mains voltage

Check the mains voltage

Full wear of brushes

Contact a service center for

replacement

Defective switch

Contact a service center for

repair or replacement

Defective engine

Contact a service center for

repair or replacement

The product does not

provide sufficient jet power

Low mains voltage

Check the mains

voltage

High material viscosity

Dilute the material (see

Setting up Procedures)

Line or nozzle clogging

Clean the line or nozzle (see

Recommended Practices)

Brush wear

Contact a service center for

replacement

The product stopped in

operation process

Lost mains voltage

Check the mains voltage

Full wear of brushes

Contact a service center for

replacement

Electromagnet winding break

Contact a service center for

repair or replacement

The result of spraying is

unsatisfactory

High material viscosity,

clots, foreign inclusions

Dilute the material (see

Setting up Procedures).

Mix thoroughly

Insufficient / excess material

consumption

Adjust the flow (see

Setting up Procedures)

Excessive / insufficient Product moving

speed

Determine the optimal speed (see

Setting up Procedures)

Line or nozzle clogging

Clean the line or nozzle (see

Recommended Practices)

Insufficient performance

See “Product does not provide

sufficient performance (material

consumption)”

Leakage

:

`

container

4 is not installed tight

;

`

gasket is damaged

;

`

crack in the nozzle, suction socket, tank.

Eliminate the leakage by

replacing the damaged part