5

GB-066B_f.

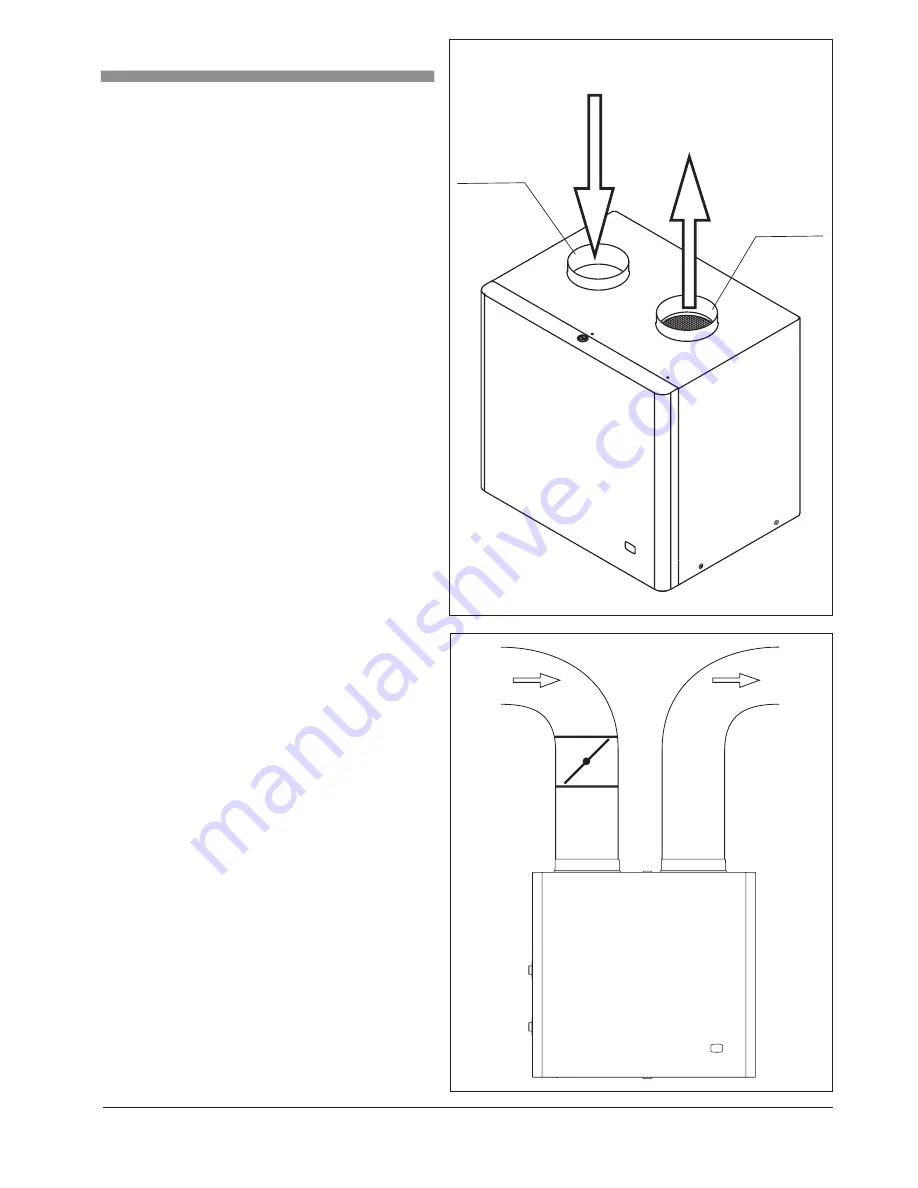

Air cables connection

Air can be extracted from the room in

which the device is mounted, another

room or from the outside of the building.

In the second and third case, the device

should result in appropriate air ducts.

In the case where the air intake on the

air outlet are on one wall at a distance

of less than 4 meters, on the air there

must be a moulder directing air flow in

a direction opposite to the air intake. At

the inlet and air outlet there are DN200

connectors. The installation should be

made of DN200 pipe using reducing

heat pump fittings on a connections. In

order to achieve optimal device param-

eters, ensure that the air flow of at 800

m

3

/h. To minimize losses associated

with air resistance, the cable must be

performed in a straight line. For DN200

the total length of the inlet and air outlet

should not exceed 10m. For wiring with

the change of direction should be taken

that the resistance of air flow through

one knee correspond to the air flow

resistance by 2 m pipe. These remarks

apply to bend pipe.

During the winter, where the air temper-

ature outside can drop below 0, there is

a risk of water freezing in the circulation

pump and the hydraulic system. This

can lead to damages of the elements

mentioned above, in order to prevent it

on the inlet channel - shut-off valve of

air supply should be installed.

air outlet

air inlet

Ø200

Ø200