I

MO-D52/R52

14

9/21 Rev. 0

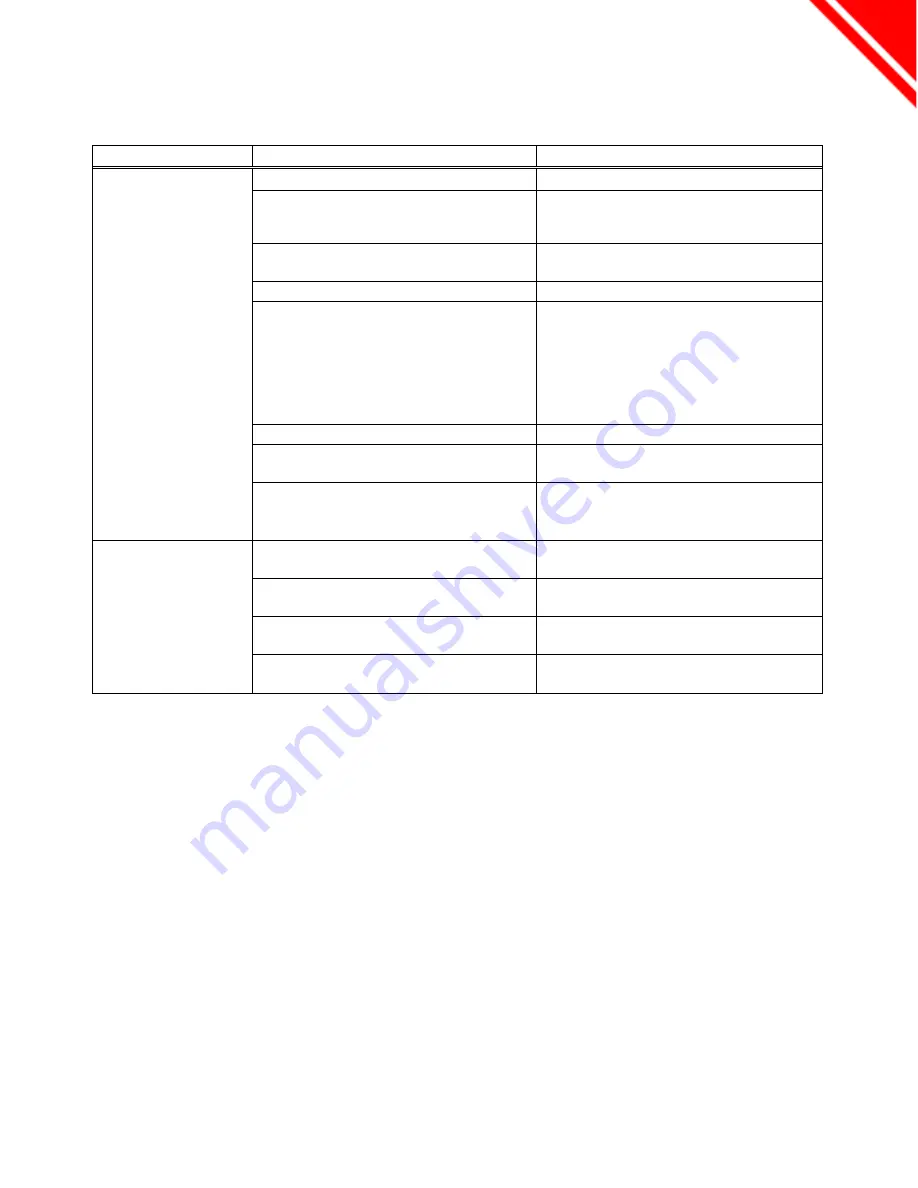

Troubleshooting and Remedies

Symptom

Cause

Remedy

No or slow operation

•

Decrease of supply air-pressure

•

Supply the specified air-pressure.

•

Clogging or leakage from the air

piping

•

Clean the piping, retighten the

connecting portion or re-arrange the

piping.

•

Air leakage from the clamping parts of

diaphragm

•

Retightening, disassemble and repair

(replacement)

•

Air leakage from the actuator rod unit

•

Disassemble it to replace the O-ring.

•

Issue with the accessories such as

positioner, booster relay, solenoid

valve and lock valve

•

Apply the specified air-pressure

directly to the instrument air

connecting port of the actuator, not

through the accessories. If no

anomaly is found with it, re-adjust the

booster relay and positioner or check

the accessories and replace them.

•

Issue with the actuator

•

Disassemble and repair the actuator.

•

The manual operation handle is set in

the manual operation position.

•

Set the handle to the position shown

in Fig. 5 or 6 in “Operation” section.

•

Sensitivity of the positioner is

insufficient.

•

Follow the instructions in the operation

manual for the positioner and replace

the capacitor spring.

Instable operation

(hunting)

•

Load change by the control fluid

(Insufficient output of the actuator)

•

Enlarge the size of the actuator.

•

Signal perturbation of the controller

•

Change the respective setting of the

controller.

•

Fluctuation of supply air pressure

•

Re-check the diameter of supply air

piping. Replace it.

•

Malfunction of the pressure reducing

valve

•

Repair the pressure reducing valve or

replace it.