Conveying Capacity

The conveying capacity depends

on the piping layaut and the type of

material to be conveyed.

In the examples the conveying

capacities apply to materials with

the following specific gravities:

Specific gravity

Material kg/m

3

Barley .......................................670

Wheat .......................................750

Oats ..........................................500

Rye ...........................................700

Maize ........................................700

Rape .........................................700

Peas .........................................800

The capacities are based on pre-

cleaned material with a moisture

content of 15% (grain, maize and

peas) or 9% (rape). Unclean crops

and higher moisture contents will

reduce the capacities.

The tables on page 14 show the

conveying capacities for barley, rye,

oats and maize with three different

types of standard suction pipelines

and one standard pressure pipe-

line. The tables on page 15 show

corresponding capacities for wheat,

rape and peas.

Each table gives the capacities of

the different blower sizes at dif-

ferent conveying distances.

The conveying distance is the total

length of all horizontal and vertical

piping on the suction and pressure

side. The length of suction hose

is included, but bends and suction

head are not taken into account.

If a long suction head is used, the

conveying distance must be in-

creased by 1.5 m. For each exten-

sion there will be a further increase

of 0.65 m.

Pneumatic conveying is based on

the use of atmospheric air to carry

the crops through the pipelines.

Thus factors influencing the air

condition (temperature, barometric

pressure) will also effect the con

-

veying capacity. The capacities

shown are based on a barometric

pressure of approx. 760 mm Hg

and an air temperature of 20 C.

The examples given are only in-

tended as a guide as many other

factors may affect the capacity.

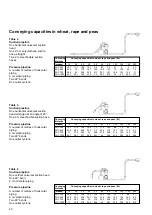

Conveying capacities in barley, rye, oats

and maize

Table 1

Suction pipeline

One horizontal universal suction head

One 2.5 m polyurethane suction hose, straight

Two 2 m steel flexible suction hoses

Pressure pipeline

A number of metres of horizontal piping

4 m vertical piping

Two 90° bends

One outlet cyclone

Table 2

Suction pipeline

One horizontal universal suction head arranged at an angle of 45°

One 2 m steel flexible suction hose

Pressure pipeline

A number of metres of horizontal piping

4 m vertical piping

Two 90° bends

One outlet cyclone

Table 3

Suction pipeline

One vertical universal suction head

One 90° bend

2 m horizontal piping

Pressure pipeline

A number of metres of horizontal piping

4 m vertical piping

Two 90° bends

One outlet cyclone

Conveying

Conveying capacities in barley, rye, oats and maize (t/h)

distance

(metres)

10 20 30 40 50 60 80 100 120 150 200

SUC

300 14 12.9 11.9 11 10.2 9.5 8.3 7.2 6.4 5.3 4

SUC

500 22.5 20.9 19.6 18.3 17.2 16.2 14.4 13 11.7 10.1 8.1

SUC

700 29.5 27.6 26 24.5 23.1 21.8 19.7 17.8 16.3 14.3 11.8

SUC

1000 45.1 42.1 39.4 37.1 34.9 33 29.7 27 24.7 21.8 18.2

Conveying

Conveying capacities in barley, rye, oats and maize (t/h)

distance

(metres)

10 20 30 40 50 60 80 100 120 150 200

SUC

300 19.6 17.7 16 14.6 13.3 12.3 10.5 9 7.8 6.4 4.7

SUC

500 31.8 28.9 26.5 24.4 22.6 21 18.3 16.1 14.3 12.2 9.5

SUC

700 42.1 38.6 35.5 32.9 30.6 28.6 25.1 22.4 20.1 17.3 13.9

SUC

1000 65.8 59.6 54.5 50.1 46.6 43.1 37.8 33.5 30.1 26 21.1

Conveying

Conveying capacities in barley, rye, oats and maize (t/h)

distance

(metres)

10 20 30 40 50 60 80 100 120 150 200

SUC

300 21 18.8 16.9

15.4 14 12.8 10.9 9.3 8.1 6.6 4.8

SUC

500 34.2 30.9 28.2 25.8 23.8 22 19.1 16.8 14.9 12.6 9.8

SUC

700 45.5 41.4 37.9 35 32.4 30.1 26.3 23.3 20.9 17.9 14.3

SUC

1000 74.3 66.6 60.3 55 50.6 46.8 40.6 35.7 31.9 27.4 22