13

Wiring

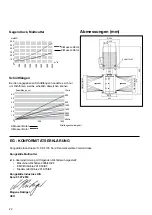

Always check the direction of rotation of the motor

prior to mounting. Rotation of the Multicutter rotor

is anti-clockwise viewed from the motor side.

If the Multicutter rotor rotates in the opposite

direction, the knives cutting edge will be damage

immediately. Do not rotate the rotor manually in

the opposite direction as even a few rotations in

wrong direction may damage the knives.

Maintenance

Always stop the Multicutter during repair and

maintenance, and make sure that it cannot be started

by mistake, while the repair and maintenance is carried

out. Always take care to switch off and lock the safety

switch (Isolator) during repair and maintenance.

Greasing

All the bearings of the Multicutter have been lubricated

for life and require no further greasing.

Motor

See the maintenance instruction from the motor

producer.

Knives

Note: For a new Multicutter, it is recommended to

check the adjustment of bottom knives after the first

1-2 hours of operation, also if new knives have been

mounted. The check is especially important when thin

materials are cut.

Then check regularly that the cutting efficiency of the

Multicutter is satisfactory. The necessity to adjust/

sharpen the knives will depend on conditions of use.

Check that the local power supply meets the

specification for the electrical equipment.

All electrical installations must be carried out according

to the current local legislation.

Take care to mount a lockable safety switch (Isolator)

for the Multicutter to ensure that it cannot be started by

accident – e.g. during repair and maintenance.

The unit may not be automatically restarted after a

power failure.

Grind /replace the knives when it is not longer possible

to adjust the Multicutter to have satisfactory cutting

efficiency.

Grinding of Rotor Knives

It is recommended to keep the original package of the

Multicutter in the event that it is necessary to have

it serviced. In order to pack the Multicutter into its

package, disassemble the motor. It is recommended

to uninstall the safety switch at the same time to avoid

dismounting electric wires.

The rotor is ground in a special grinding unit to obtain

appropriate cutting surface of the knives and exact

centering of the rotor axis. See: separate grinding

instructions for the Multicutter.

To avoid longer periods of downtime, Kongskilde can

supply newly ground replacement rotors.

Kongskilde recommends the replacement of the

Multicutter bearings at the same time as grinding of

the rotor. Only original bearings for the Multicutter must

be used (see: list of spare parts). The bearings used

in the Multicutters are special precision bearings. The

use of standard bearings may reduce cutting efficiency

of the Multicutter.