14

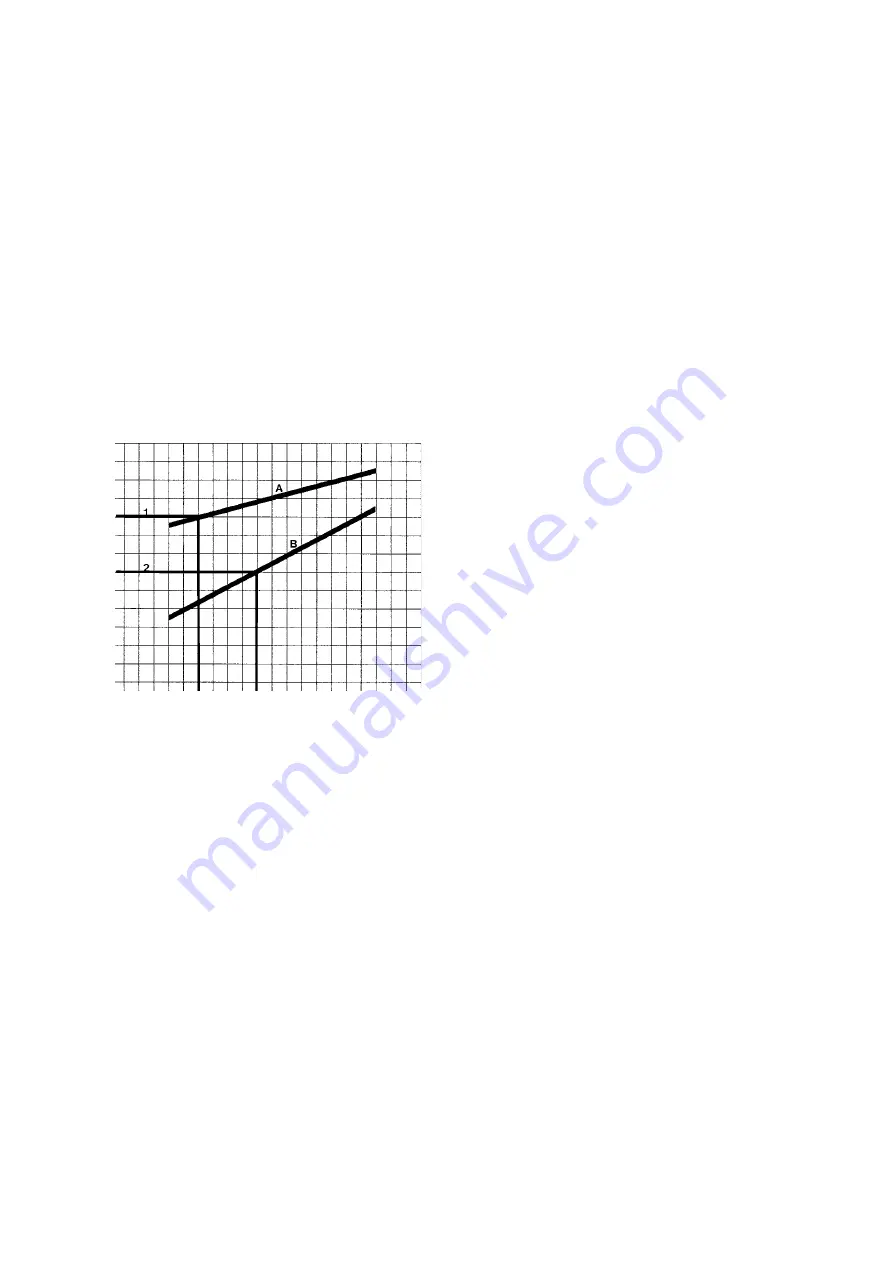

Before starting the grading of the malting barley, it

is advantageous to know the grading of the starting

material (the unsorted grain). This may be deter-

mined manually by means of test screens, or you

can ask a feedstuff dealer to test one or more sam-

ples.

Based on the grading of the sample and the outer

screen, use the diagram overleaf to indicate the

capacity required to obtain a final grading result of

90 % grains exceeding 2,5 mm.

Recommended capacities for malting barley

grading

(A) Screen 2,5 x 16,5 mm

(B) Screen 2,65 x 16,5 mm

The recommended capacities are subject to the

following conditions

Final sorting result: ................................

90 % grains

exceeding 2,5 mm

Moisture content: .....................................

Max. 14 %

(well threshed malting barley)

Inclination of cleaner:.............................................

9°

Examples:

1. Starting material sorting: ...........

82 %

Desired final sorting:

..................

90 %

Outer screen slots: ....................

2,5 x 16,5 mm

Recommended capacity

according to graph: ........................... 7 t/hour

2. Starting material sorting: ...........

76 %

Desired final sorting:

..................

90 %

Outer screen slots: ....................

2,65 x 16,5 mm

Recommended capacity

according to graph: ....................13,5 t/hour

If the starting material sorting is lower than the

curve of the outer screen used, this means that two

cycles will be required to reach a final sorting result

of 90 %.

Initial adjustment for malting barley grading

Declination: ...................

9°

Inner screen (mm): ........

Ø9 / Ø9 / Ø7,4/Ø7,4/Ø7,4

Outer screen (mm): .......

2,5 x 16,5 or 2,65 x 16,5

Selection of inner screen

The selection of the inner screen depends to a

high degree on the quality of the threshing and the

expected capacity. If the crop is reasonably well

threshed, it will sometimes be advantageous to

replace the 2nd section of the inner screen of Ø9

mm by an Ø7,4 mm screen and thereby obtain a

cleaner crop.

Selection of outer screen

The selection of the outer screen depends on the

desired capacity.

Where a high capacity is desired, the 2,65 x 16,5

mm screen should be selected. You risk, on the

other hand, a separation of good grains of 3 - 12 %

depending on the starting material grading.

The 2,5 x 16,5 mm screen should be selected

where a lower capacity and perhaps two cycles can

be accepted to achieve a final grading result of 90 %.

Control of grading

After the initial adjustment of the KDC 8000 and

operation at the capacity stated for two or three

minutes, samples should be taken to check if the

desired final result has been achieved.

When taking samples at the cleaner outlet, it is

recommended to collect the entire grain flow for a

short moment before selecting the desired quantity

from the collected grain.

The grading rate of the sample is found by means

of test screens. If the percentage is too low, reduce

the capacity, and if it is too high, increase the ca-

pacity. As crops will vary, however, it will be wise to

allow for a minor safety margin.

If the capacity is changed, new samples will have

to be taken. Continue this way until the desired

grading result of the finished product has been

obtained. When the correct capacity setting has

been reached, it is recommended to deliver a sam-

ple of the finished product to the feedstuff dealer for

testing, as the test screens are intended as a guide

only.

Starting material sorting %

Capacity (t/h)

90

88

86

84

82

80

78

76

74

72

70

68

66

64

0 2 4 6 8 10 12 14 16 18 20

Summary of Contents for KDC 8000

Page 1: ...KDC 8000 Combi cleaner Manual Brugsanvisning...

Page 35: ...35...