page

59

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

REFRIGERANT SYSTEM REPAIR

Brazing

• In the event of a leak, obstruc on, or trouble in the refrigerant system of the unit,

replace or repair the defec ve component. A er replacing defec ve component,

braze all connec ons.

1) Proper brazing techniques

• When brazing, use a slightly reduced fl ame. Oxyacetylene is commonly used since

the fl ame condi on can be easily judged and adjusted. Unlike gas welding, a sec-

ondary fl ame is used for brazing. Properly preheat the base metal according to the

shape, size and thermal conduc vity of the brazed fi

ng.

• The most important point in fl ame brazing is to bring the en re brazed fi

ng to

a proper brazing temperature. Care should be taken not to cause overfl ow of the

brazing fi ller metal, oxida on of the brazing fi ller metal, or fi ller metal deteriora-

on due to overhea ng the fl ux.

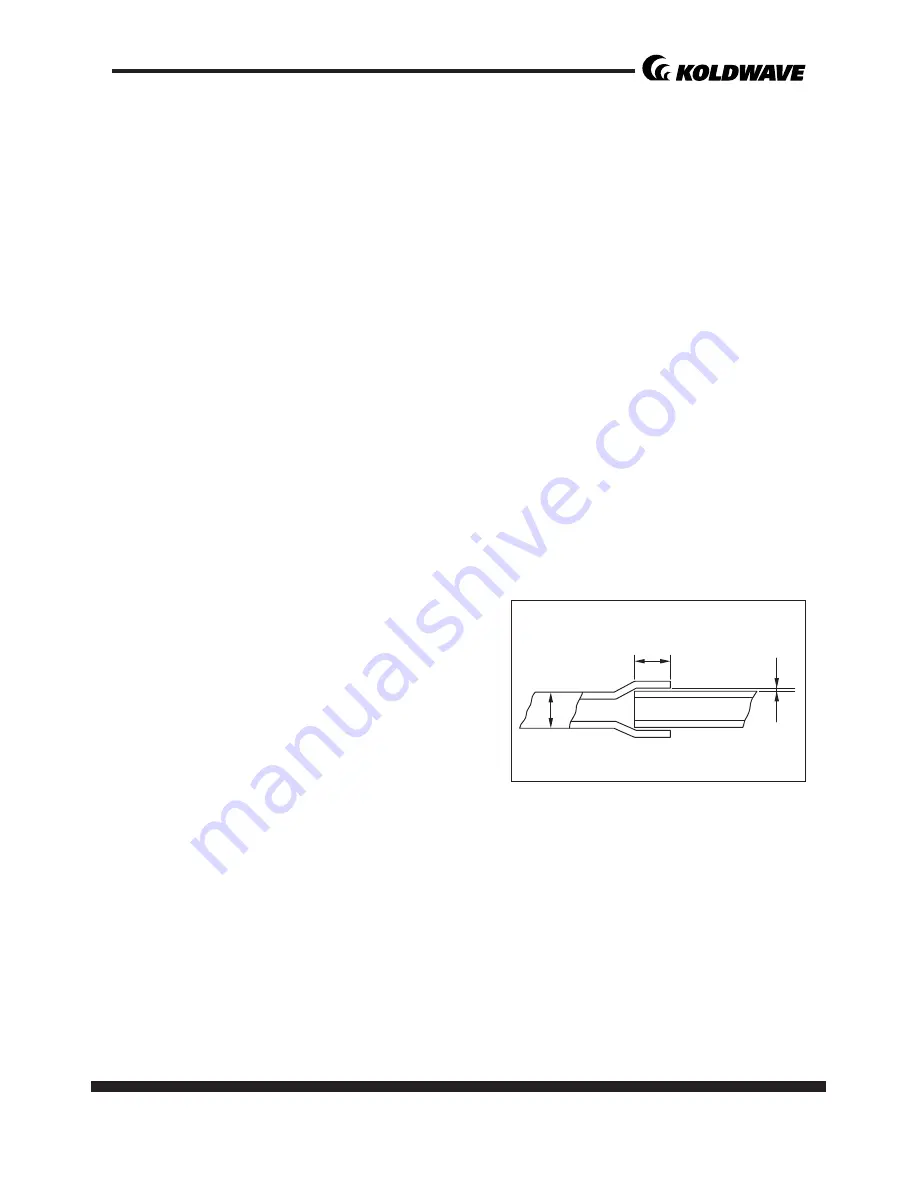

2) Brazed fi

ngs and fi

ng clearance

• In general, the strength of the brazing fi ller metal is lower than that of the base

metal. As such, the shape and clearance of

brazed fi

ngs are very important. Concern-

ing the shape of brazed fi

ngs, adhesive

area must be maximized. In addi on, the

clearance of the brazed fi

ng must be mini-

mized so that the brazing fi ller metal will

fl ow into the fi

ng via capillary ac on.

Clearance

Clearance From The Pipe Fing and Tubing.

0.001~0.003 in

(0.025~0.075 mm)

a

a