2

111864-2-

BA

(-)

Kohler Co., Kohler, WI

TOOLS AND MATERIALS REQUIRED

10” adjustable wrench

12” pipe wrench

Metal file (file cut)

Tape measure

Tubing cutter

Level

Hacksaw

Putty knife

Screwdriver

Toilet gasket (wax seal)

Toilet T-bolts (2), 5/16” diameter

Toilet supply shut-off valve, 3/8” recommended

(If existing toilet does not have a shut-off valve below the

tank, install shut-off valve before installing new toilet. See

Page 3.)

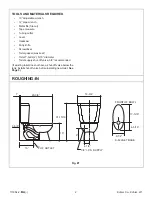

ROUGHING-IN

29-3/8”

15”

Fig. #1

3/8” I.P.S. SUPPLY

C

L OF OUTLET

FRONT OF BOWL

K-4229-ET BASE

1”

19-3/4”

17-5/16”

4-5/16”

9-1/2”

4-1/8”

9”

31-15/16”

3-5/8”

10”