Install Closure Plate Assembly

Sealant Pattern and Torque Sequence

1

10

8

6

4

2

9

7

5

3

Install Stator and Backing Plates

1. Apply pipe sealant with Te

fl

on

®

(Loctite

®

592™

Thread Sealant or equivalent) to stator mounting

holes.

2. Position stator aligning mounting holes so leads are

at bottom, towards crankcase.

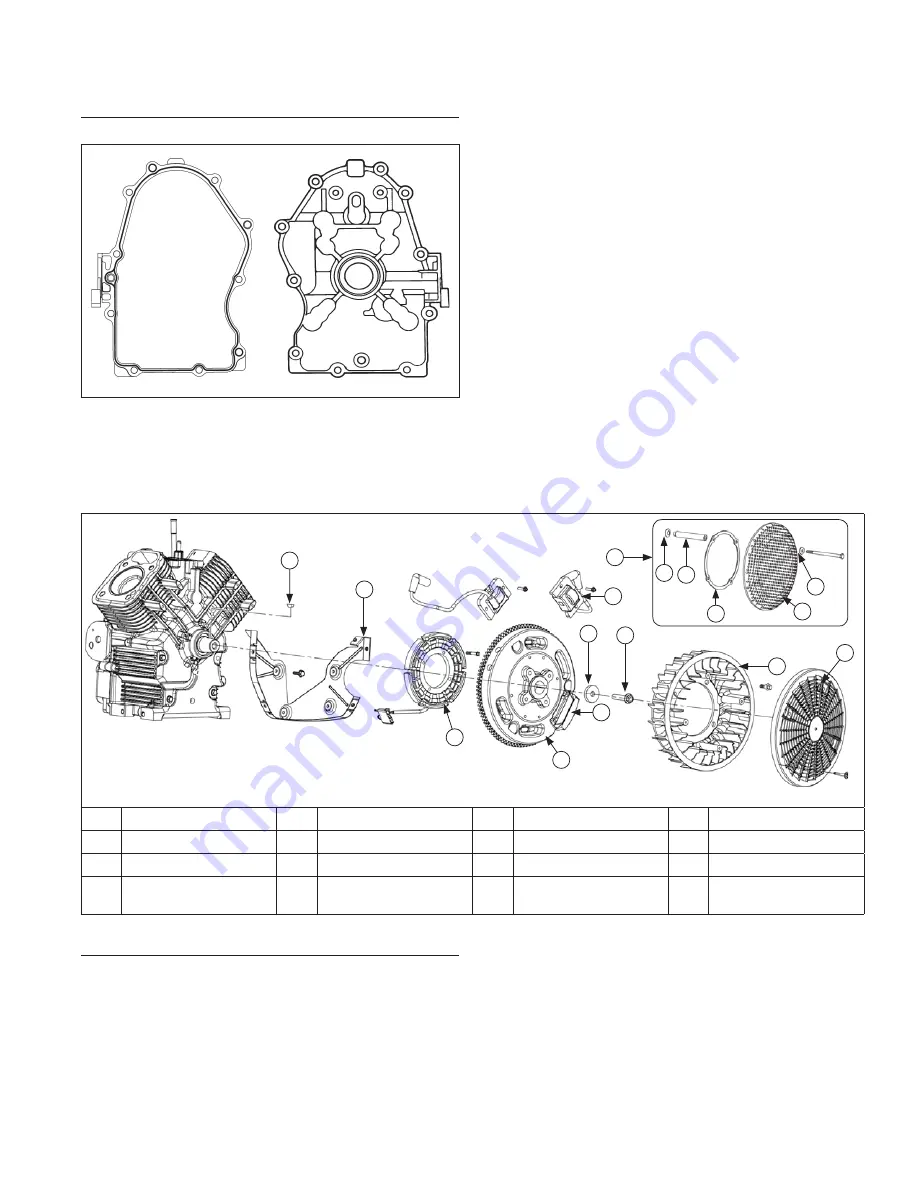

Flywheel/Ignition Components

F

G

E

C

K L

O

M

N

H

P

B

I

D

J

A

A

Debris Screen

B

Fan

C

Flywheel Screw

D

Washer

E

Flywheel

F

Magnet

G

Stator

H

Ignition Module

I

Backing Plate

J

Woodruff Key

K

Spring Washer

L

Spacer

M

Ring Support

N

Metal Debris Screen

O

Washer

P

Metal Debris Screen

Assembly

RTV sealant is used as a gasket between closure plate

and crankcase. Always use fresh sealant. Using

outdated sealant can result in leakage.

1. Be sure sealing surfaces have been cleaned and

prepared. Install a new O-ring in closure plate.

2. Check to make sure there are no nicks or burrs on

sealing surfaces of closure plate or crankcase.

3. Apply a 1.5 mm (1/16 in.) bead of sealant to sealing

surface of closure plate.

4. Make sure end of governor cross shaft is lying

against bottom of cylinder 1 inside crankcase.

5. Install closure plate to crankcase. Carefully seat

camshaft and crankshaft into their mating bearings.

Rotate crankshaft slightly to help engage oil pump

and governor gear meshes.

6. Install screws securing closure plate to crankcase.

Torque fasteners to 24.4 N·m (216 in. lb.) following

sequence. On some engines one mounting screw is

plated. Plated screw is typically installed in hole

location 6.

3. Install and torque screws to 6.2 N·m (55 in. lb.).

4. Route stator leads in crankcase channel, then install

backing plates and stator wire bracket (if used).

Secure using screws. Torque screws to 7.3 N·m

(65 in. lb.).

Reassembly

59

24 690 34 Rev. D

KohlerEngines.com