LFM

Page 4

LFM K03/0422

4. Regulation Use

The LFM is a new flowmeter designed for use on clean low-viscosity liquids and

is particularly suitable for dosing and filling applications. Extremely low flow rates

can be measured down to 0.005 l/min. Care should be taken that liquid which

may attack the wetted parts of the flowmeter are not used.

Please ensure that all steps in this manual are observed as the flowmeters war-

ranty does not cover damage resulting from failure to comply with these

instructions.

We recommend a filter with 40 µm mesh size.

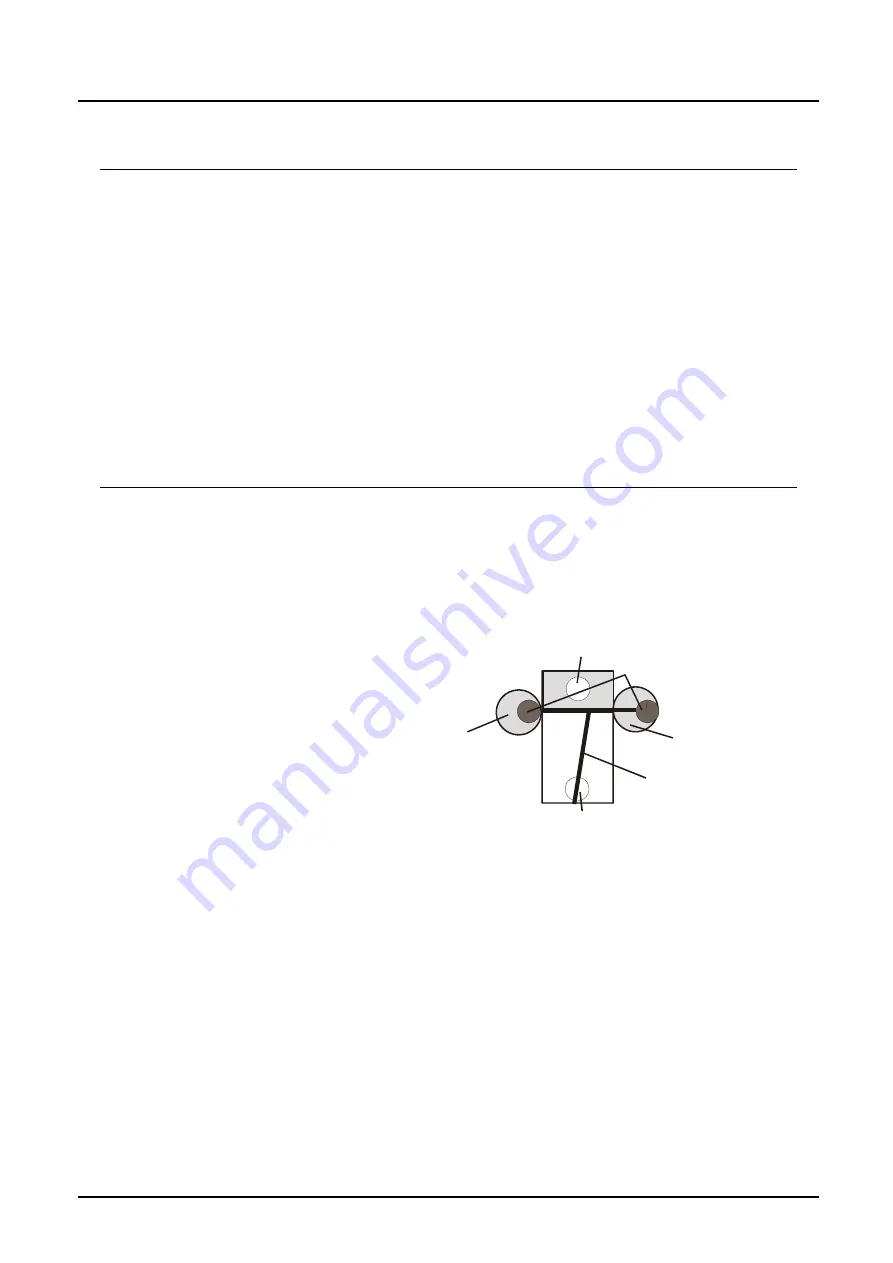

5. Operating Principle

The measuring mechanism is based on a dual-ring piston pendulum. The right-

hand measuring chamber is opened, and the left-hand chamber closed, by the

pendulum arm that is inclined to the right. The pressure of the forced liquid acts

on the upper surface of the piston pendulum. The right-hand ring piston is

pressed clockwise downwards, and the left-hand ring piston is pressed clockwise

upwards by the larger surface (opened measuring chamber) on the right. Thus

the right-hand measuring

chamber is closed, and

the left-hand chamber

opened. The surface on

the left is now greater –

causing motion in the

opposite direction. This

cycle is repeated with

continuous flow at a rate

proportional to the flow

rate 1–230 cycles/s. A volume of approximately 0.01 cm

3

is displaced per pass.

The built-in carrier frequency transducer senses the oscillating motion of the

piston pendulum and pendulum arm without contact through the case, and

outputs a digital signal with a frequency proportional to the volumetric flow. Due

to the negligible pendulum mass and minimum friction loss, the LFM detects

minimum volumetric flow rates. Leakage loss is minimized by the piston design,

which also provides good linearity and repeatability.

Inlet bore

Outlet bore

Meas. Chamber 1

Pendulum

Ring piston

Meas. Chamber 2