Servicing

Diaphragm pump N87.9 EX

28

Translation of Original Operation and Installation Instruction, english, KNF 323252 04/21

WARNING

Risk of explosion from formation of potentially ex-

plosive atmosphere

Leaky connections can result in dangerous poten-

tially explosive atmospheres.

à

Make certain that all elastomer parts are un-

damaged, clean and correctly installed.

à

Check the pneumatic connections of the pump

for leaks.

à

Work with care during service work.

à

Replace defective parts immediately.

WARNING

Health hazard due to dangerous substances in the

pump

Depending on the medium being transferred,

caustic burns or poisoning is possible.

à

Wear protective equipment if necessary, e.g.,

protective gloves, goggles.

à

Clean the pump with suitable measures.

Removing pump head

1. Mark the pressure plate, head plate, intermediate plate and housing

with a felt-tip pen ( Fig. /1) to ensure proper mounting.

2. Remove the housing cover ( Fig. /3).

WARNING

Risk of explosion from damage

If the housing cover is bent or if the paint is dam-

aged, there is no risk of explosion.

à

Perform the work steps carefully and without

the use of force.

3. Loosen the four fastening screws (Fig. 4/2) and remove the housing

cover (Fig. 4/3).

The counterweight is visible.

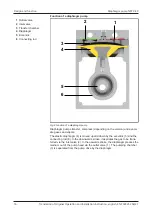

Fig.4 Replacing the structured di-

aphragm

4. Loosen the four screws ( Fig. 4/1) and remove the pressure plate ( Fig.

4/4).

5. Remove the screw covers ( Fig. 4/2); loosen the two screws ( Fig. 4/3)

and remove the head plate ( Fig. 4/5) and the intermediate plate ( Fig.

4/6).

The structured diaphragm (7) is visible.

Replacing the structured diaphragm

1. Turn the pump to the side; this keeps the shim rings (10) and the disc

springs (11) from falling into the pump chamber when removing the

structured diaphragm (7).

2. Move the structured diaphragm (7) by turning the counterweight to the

upper reversal point.

3. Lift the structured diaphragm (7) onto opposing side edges; hold the

structured diaphragm and unscrew it counterclockwise.