Technical Data

17

DG 2.1S user manual V6880, version

3.3

Device defect

Intruding liquids can cause damage to the device.

Place solvent bottles next to the device or in a solvent tray.

Moisten the cleaning cloth only slightly.

What is to be done if the degasser leaks?

If the degasser leaks, solvent can reach the motor and from there reach the

degasser exhaust and flow out. In this case, the automatic pump control will

switch the device off.

Inform the Technical Support of KNAUER.

Tightening Screw Fittings

1. If the screw fitting of the solvent tube is untight, carefully tighten the screw

fitting.

2. If it still leaks, loosen and check the screw fitting.

3. If no damage or deformation is visible at the seal ring and at the screw fit-

ting, repeat step 1.

4. If it still leaks, replace the screw fitting and seal ring.

Preventative Measures

To ensure that the degasser can constantly run at maximum capacity, pay

attention to the following:

Only use ultrapure solvent as mobile phase. If water is used as solvent, it also

has to fulfill this standard or be filtered and deionized.

Filter all solvents to prevent clogging.

To dry the degasser, only use ultrapure gas.

Observe the information on switching off the degasser.

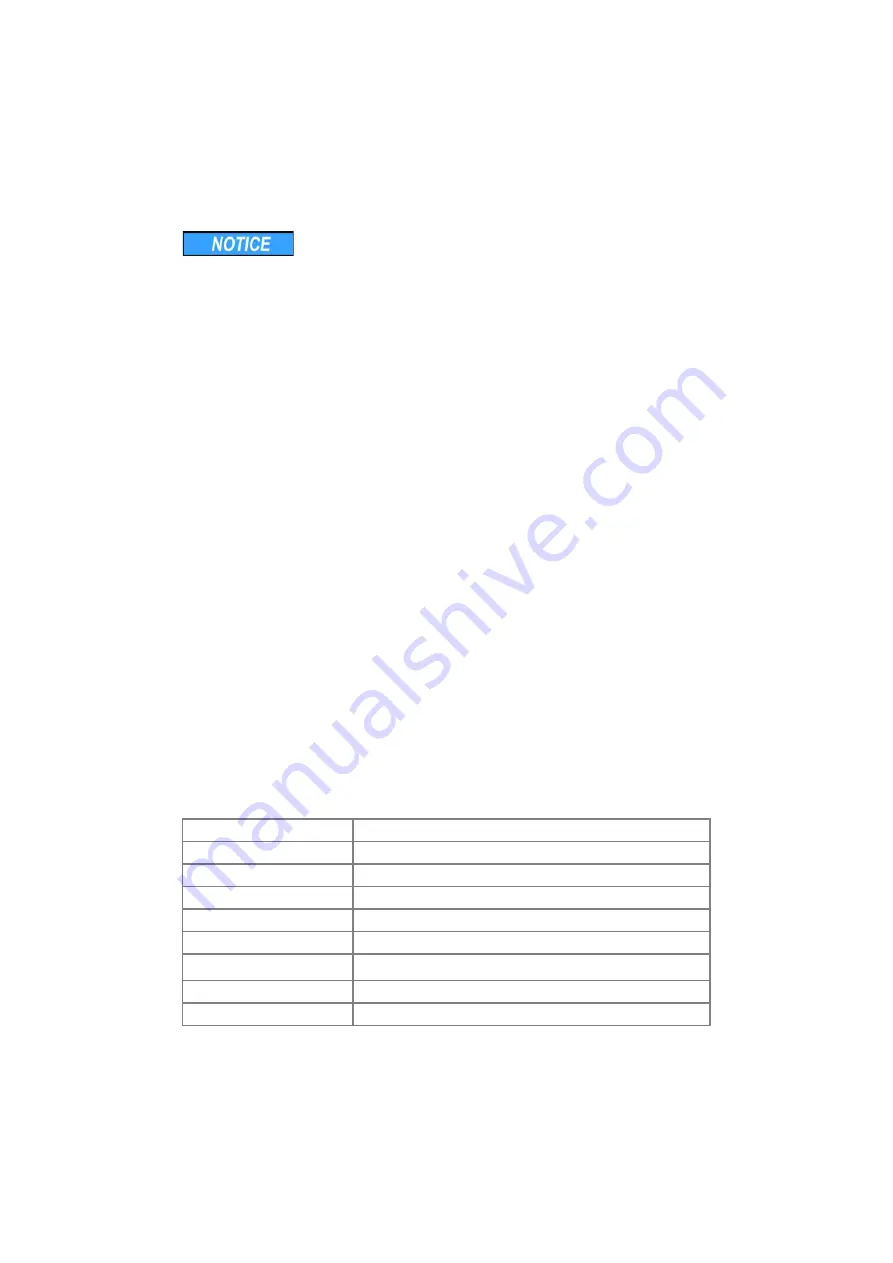

Technical Data

Channels

2

Maximum flow rate

10 ml/min

Degassing method

gas permeation through a fluoropolymer membrane

Dead volume

approx. 285 μl per channel

Pressure decline

1.37 mm (Hg/ml/min)

Max. pressure stability

7 bar

Wetted materials

PEEK, glass-filled PTFE, Teflon AF

®

Display

1 LED

Dimensions

121 x 138 x 190 mm