6

13. Be sure the timer start and timer reset button covers align

with contact points on control board.

14. Be sure the LED lens and digital display line up with holes in

bezel.

15. Using thumbs, press control PCB board until it clamps

securely into cradle.

16. Reassemble the ferrite bead fastener with one Phillips screw.

Be sure 5-pin connector is securely connected to power

supply PCB. Reassemble base to cradle.

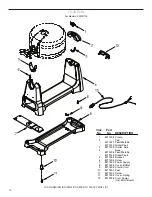

Button Replacement

There are three (3) push buttons on the control bezel: power

on/off, timer start and timer reset:

1. Unplug

the

waffl e baker.

2. Remove the base; see Component Access.

3. Remove one screw from the ferrite bead fastener.

2.

Using thumbs, push down on control PCB board (located in

cradle arm) until clamps release.(See Figure 1)

3.

Place tape over button front. This will help prevent losing the

button’s small spring.

4.

Reach inside the waffl e baker cradle and grasp the button

cover sleeve with needle nose pliers. Pull straight back to

release the sleeve.

5.

Remove tape and pull out button cover and shaft from bezel,

being careful not to lose small spring.

6.

Insert new button shaft through bezel hole. Be sure spring is

between button top and outer bezel. (See Figure 6)

7.

Slide button cover over shaft. Add a small drop of super glue

or solder into the cover hole. (See Figure 7)

8.

Be sure button cover lines up with contact point on control

PCB board.

9.

Using thumbs, press control PCB board until it clamps

securely into cradle. Reassemble.

10. Check each button and the timer adjustment knob to make

sure each works properly.

Figure 6

Figure 7

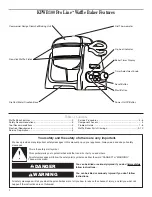

CONTROL PCB BOARD REPLACEMENT

The control board regulates the light, timer and power on/off

button. It is located in the cradle.

1. Unplug

the

waffl e baker.

2. Remove the base; see Component Access.

3.

Remove one Phillips screw from the ferrite bead fastener.

Then remove the white, 5-pin connector from the power

PCB. This will allow for easy access to the control PCB.

4.

Remove the timer adjustment knob; see Timer Adjustment

Knob Replacement instructions.

5.

Remove the start and reset buttons; see Button Replacement

instructions.

6.

Remove the control PCB from the cradle. Remove (4) four

Phillips screws from the control PCB plastic cover.

7.

Remove three (3) white pin connectors from bottom of

control board; two (2), 2-pin connectors and one (1), 5-pin

connector.

8.

Replace the old control PCB with the new control PCB. Be

sure three white (3) pin connectors are connected securely

to board; two (2), 2-pin connectors and one (1), 5-pin

connector.

9.

Reassemble with new control PCB board to the plastic cover

with 4 Phillips screws. Slide control board into cradle.

10. Reassemble the timer adjustment knob; see Timer

Adjustment Knob Replacement instructions.

12. Slide button cover over shaft. Add a

small drop of super glue or solder into

the cover hole. (See Figure 7)

11. Insert button shaft through bezel hole. Be sure spring is

between button top and outer bezel. (See Figure 6)

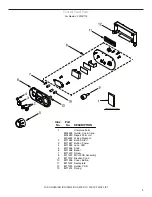

POWER SUPPLY PCB REPLACEMENT

The power supply printed circuit board (PCB) provides DC voltage

to power the control PCB located in the cradle arm and AC

voltage to the heating elements in the waffl e plates. (See Figure 5)

1. Unplug the waffl e baker.

2. Remove base; see Component Access.

3.

Remove six (6) blue-capped black and white AC leads from

the power supply PCB located in the base.

4.

Remove white, 5-pin connector from the PCB.

5.

Remove four (4) Phillips screws from PCB; remove board

from base.

6.

Reassemble with new board. Be sure six (6) blue-capped

leads and white 5-pin connector are connected securely in

their proper positions. Replace base cover.

Figure 5