1-2

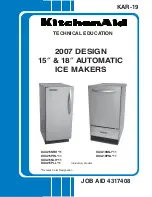

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

SERIAL NUMBER

MODEL NUMBER

K UI A 15 NR H S

0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

UI = UNDERCOUNTER ICE MAKER

MERCHANDISING SCHEME

A = ARCHITECT

C = CULINARY & ARCHITECT II

S = STANDARD

O = OUTDOOR

V = SIGNATURE SERIES

CAPACITY / SIZE / SERIES / CONFIGURATION

15 = 15" WIDE

18 = 18" WIDE

FEATURES

PR = PUMP, RIGHT HAND DOOR SWING

PL = PUMP, LEFT HAND DOOR SWING

PN = PUMP, NON-REVERSIBLE DOOR SWING

NR = NON-PUMP, RIGHT HAND DOOR SWING

NL = NON-PUMP, LEFT HAND DOOR SWING

NN = NON-PUMP, NON-REVERSIBLE DOOR SWING

YEAR OF INTRODUCTION

H = 1999, J = 2000, K = 2001, L = 2002, S = 2006, T = 2007

COLOR CODE

B = BLACK, W = WHITE, S = STAINLESS

T = BISCUIT, M = METEORITE

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

E T 04 54321

DIVISION RESPONSIBILITY

E = EVANSVILLE, IN

YEAR OF PRODUCTION

T = 2006, U = 2007

WEEK OF PRODUCTION

04 = 4th WEEK

PRODUCT SEQUENCE NUMBER

Summary of Contents for Kitchen Aid KAR-19

Page 57: ...6 5 DIAGNOSTIC FLOW CHARTS FOR ICE MAKER CONTROL BOARD OVERVIEW ...

Page 61: ...6 9 Harvest Bin Not Full ...

Page 62: ...6 10 Harvest Bin Full ...

Page 66: ...6 14 NOTES ...

Page 67: ...7 1 WIRING DIAGRAM STRIP CIRCUITS WIRING DIAGRAM MEASURED FILL WATER VALVE ...

Page 70: ...7 4 NOTES ...

Page 74: ......