INSTALLING FRONT RAIL AND TUBE ASSEMBLY

Place and align the mounting holes of the front rail and tube

assembly (A) Fig.1 with the holes in the front lip of the table (C) and

extension wings (D & E). Install the front rail and tube assembly to

the table and extension wings using 4 countersunk head bolts, 8

washers, 4 spring washers and 4 hex. nuts.

Before securing it in place, adjust it up or down to ensure the front

rail edge is set at 1/8” below the lowest edge of the miter gauge

T-slot. Once adjusted, tighten all 4 countersunk head bolts.

INSTALLING REAR RAIL

Place and align the mounting holes of the rear rail (B) Fig.1 with the

holes in the rear lip of the table (C) and extension wings (D & E).

Install the rear rail to the table using 2 hex. bolts and 2 washers.

Then 2 use hex. bolts, 4 washers, 2 spring washers and 2 hex.

nuts to fix the rear rail to the extension wings. Before securing it in

place, adjust it up or down to ensure the rear rail edge is set flush

with the lowest edge of the miter gauge T-slot (to allow free

movement of the miter gauge). Once adjusted, tighten all 4 bolts.

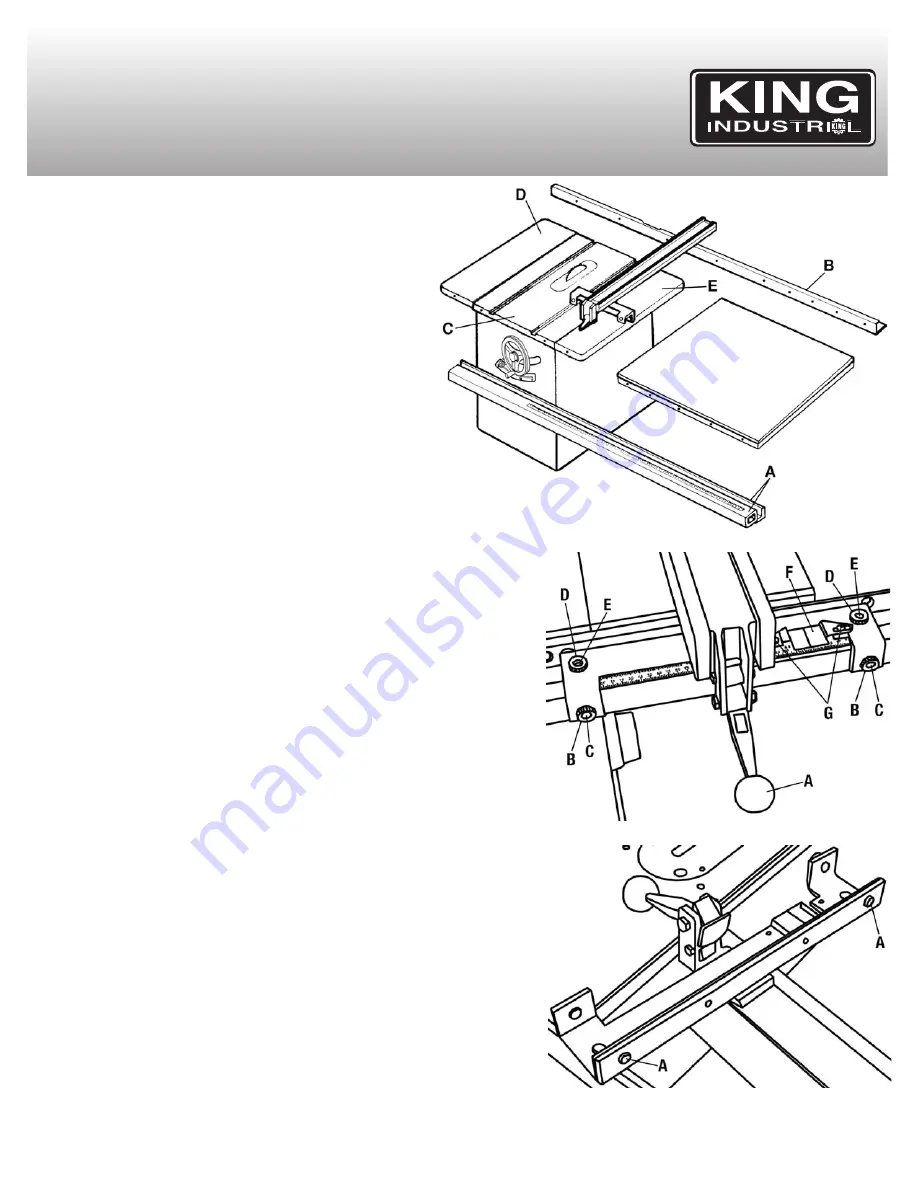

ADJUSTING RIP FENCE

The rip fence must be perfectly aligned with the table T-slot, to verify this, place rip

fence on table and align the edge of the rip fence with the table T-slot, lower the

locking lever (A) Fig.2 to lock it into place. Check to see if the edge of the rip fence

and the table T-slot are parallel. If they are not parallel, unlock the rip fence and turn

it upside down as shown in Fig.3. Adjust the set screws (A) Fig.3 in or out, verify your

adjustment, repeat if necessary.

The lock lever pressure can be adjusted by loosening the front lock nuts (B) Fig.2

and adjusting the set screws (C) the same amount, make sure the fence remains

parallel with the table T-slot. Retighten lock nuts.

To set the fence perpendicular to the table, place a square on the table and against

the side of the fence, loosen the top lock nuts (D) and adjust the set screws (E) until

the fence is perpendicular. Retighten lock nuts.

The pointer window (F) Fig.2 position can be adjusted if needed, loosen pan head

screws (G), reposition the pointer window and retighten pan head screws.

ASSEMBLY AND ADJUSTMENTS

FIGURE 1

FIGURE 2

FIGURE 3