PNEUMATIC LEVEL CONTROLLER

PNEUMATIC LEVEL CONTROLLER

MODEL: GEN 3

Installation, Operation & Maintenance Guide

MODEL: GEN 3

Installation, Operation & Maintenance Guide

www.kimray.com

10

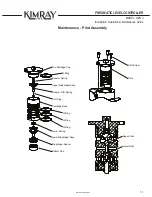

Maintenance - Pilot Assembly

Pilot - Disassembly

Step 1 – Remove 3 socket screws (1/8" hex key) holding

pilot to enclosure. Remove pilot by prying under flats and

then pulling pilot out.

Step 2 – Remove and discard 4 O-rings around outside

of pilot cartridge.

Step 3 – Place flats on lower pilot cartridge into vise or

hold in place with wrench.

Step 4– Unthread and carefully remove flanged top pilot

cap to (3/8" socket).

Step 5 – Carefully remove upper diaphragm assembly to

avoid damaging conical spring. If diaphragm is stuck, do

not pry with screwdriver. Use pliers to pull out diaphragm

assembly.

To remove pilot plug, turn pilot assembly over and it

will fall out. Inspect pilot plug and seat surfaces shown

for scratches, pitting, or any other potential leak paths.

Clean off any debris.

Step 6 – Holding flats of pilot cartridge in place, unthread

and remove bottom pilot cap (3/8" socket).

Step 7 - Remove lower diaphragm assembly and lower

spring. If diaphragm is stuck, do not pry with screwdriver.

Use pliers on stem of actuator to pull out diaphragm

assembly.

Step 8 - Clean out all communication holes.

Pilot - Reassembly

Step 1 – Clean pilot cartridge and install pilot plug, small

diameter first, into the side of the cartridge with the upper

seat.

Step 2 – Place conical spring on upper diaphragm

assembly. Apply grease to assembly where spring rests.

Step 3 – Place booster spring in top cap. Apply grease in

top cap where spring sets.

Step 4 – Place diaphragm assembly in pilot block such

that conical spring contacts pilot plug.

Step 5 – Screw the top cap (3/8" socket) into the pilot

cartridge. Ensure that spring is centered on the upper

diaphragm assembly. Torque top cap to 25-30 in·lbs.

Step 6 – Place lower spring on lower diaphragm

assembly and install into lower portion of pilot cartridge.

Step 7 – Install lower cap (3/8" socket) over lower

diaphragm assembly. Torque lower cap to 25-30 in·lbs.

Step 8 – Install 4 new O-rings into grooves on outside of

cartridge. Apply grease to O-rings.

CAUTION:

Do not allow grease to get on any other

components or into communication holes. If grease gets

into pilot plug/seats, or blocks communication paths, the

pilot might not operate correctly.

Step 9 – Insert pilot cartridge into enclosure.

Step 10 – Install 3 socket screws (1/8" hex key) to retain

pilot.