8 PLZ2004WB/PLZ2004WHB

Cleaning the Dust Filter

A dust filter is installed on the inside of the louver on the front panel.

Periodically clean the filter to prevent clogging.

CAUTION

•

Clogged dust filters hinder the cooling of the inside of the

instrument and can cause a malfunction and shortening of the

service life.

•

When the Booster is in operation, air is sucked through the dust

filter to cool the load booster. If moister is included in the dust

filter, the temperature or humidity inside the Booster increases

and may cause a malfunction.

■

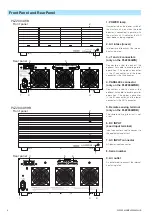

Cleaning the PLZ2004WB's dust filter

1

Remove the louver from the panel by placing a finger

on the 2nd level of the louver and pulling down the

1st level while pulling it toward you.

If the louver does not come off easily, pressing down the top

level of the louver will ease the work.

1st level

2nd level

2

Remove the dust filter from the inside of the louver

and clean it.

Remove the dust on the dust filter such as by using a vacuum

cleaner. If the filter is extremely dirty, clean it using a water-

diluted neutral detergent and dry it completely.

Dust filter

Louver

Tab

3

Attach the dust filter to the louver.

Firmly attach the dust filter so that the louver's tabs protrude out

of the top of the dust filter.

4

Attach the louver to the panel by pulling up on the

louver while holding the 2nd level of the louver with

your hand until the pin is fixed in place.

Pin

■

Cleaning the PLZ2004WHB's dust filter

1

Remove the lower louver from the panel.

While lifting the bottom of the removal mark with your finger tips,

slide the entire louver to the right. Then, pull it toward you.

POWER

ELECTRONIC LOAD

PLZ2004WHB

2000W

5-650V

0-100A

①

②

②

While lifting the bottom of the removal mark with your finger tips (

①

),

slide the entire louver to the right (

②

).

Removal mark

Louver

2

Remove all the remaining louvers in the same manner

as was shown in step 1.

3

Remove the dust filter from the inside of the louver

and clean it.

There is a hook on the louver tab. Be sure not to get the dust

filter caught in the hook when removing the dust filter from the

louver.

Remove the dust on the dust filter such as by using a vacuum

cleaner. If the filter is extremely dirty, clean it using a water-

diluted neutral detergent and dry it completely.

Hook

Hook

Louver

Dust filter

Tab

Guide

4

Align the dust filter along the guide and attach it to

the louver.

Be sure to attach it firmly until the tab hooks of the louver

completely passes through the dust filter.

5

Attach the upper louver first.

Align the tab on the inner side of the louver to the panel groove

and slide the louver to the left to attach it. You can easily attach

the louver by aligning the long tabs (five locations) with the

grooves.

Tab (long)

Tab (short)

Upper louver

Groove for attaching the louver

Pass the long tabs on the back side of the louver through

the grooves on the panel indicated by circles.

Slide the louver to the left to lock the louver in place.

6

Attach all the remaining louvers in the same manner

as was shown in step 5.