29

9 - INSTALLATION

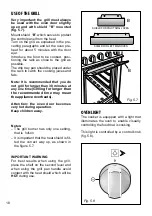

650 mm

500 mm

450 mm

200 mm

Fig. 9.1

The cooker must be installed by a qualified technician and in compliance with

local safety standards.

This cookers has class “2/1” overheating protection so that it can be installed

next to a cabinet.

If the cooker is installed adjacent to furniture which is higher than the gas hob cooktop, a

gap of at least 200 mm must be left between the side of the cooker and the furniture.

The furniture walls adjacent to the cooker must be made of material resistant to heat.

The veneered synthetical material and the glue used must be resistant to a temperature

of 90°C in order to avoid ungluing or deformations.

The cooker may be located in a kitchen, a kitchen/diner or bed-sitting room but not in a

room containing a bath or shower.

Curtains must not be fitted immediately behind appliance or within 500 mm of the sides.

If the cooker is located on a pedestal it is necessary to provide safety measures to pre-

vent falling out.

It is essential that the cooker is positioned as stated below.