Page

16. Develop a sense of personal safety awareness. Observe all safety regulations. Be on the lookout for hazardous conditions

and discuss control of them with your supervisor.

17. Always follow all operating procedures outlined in ANSI B65.5-1996

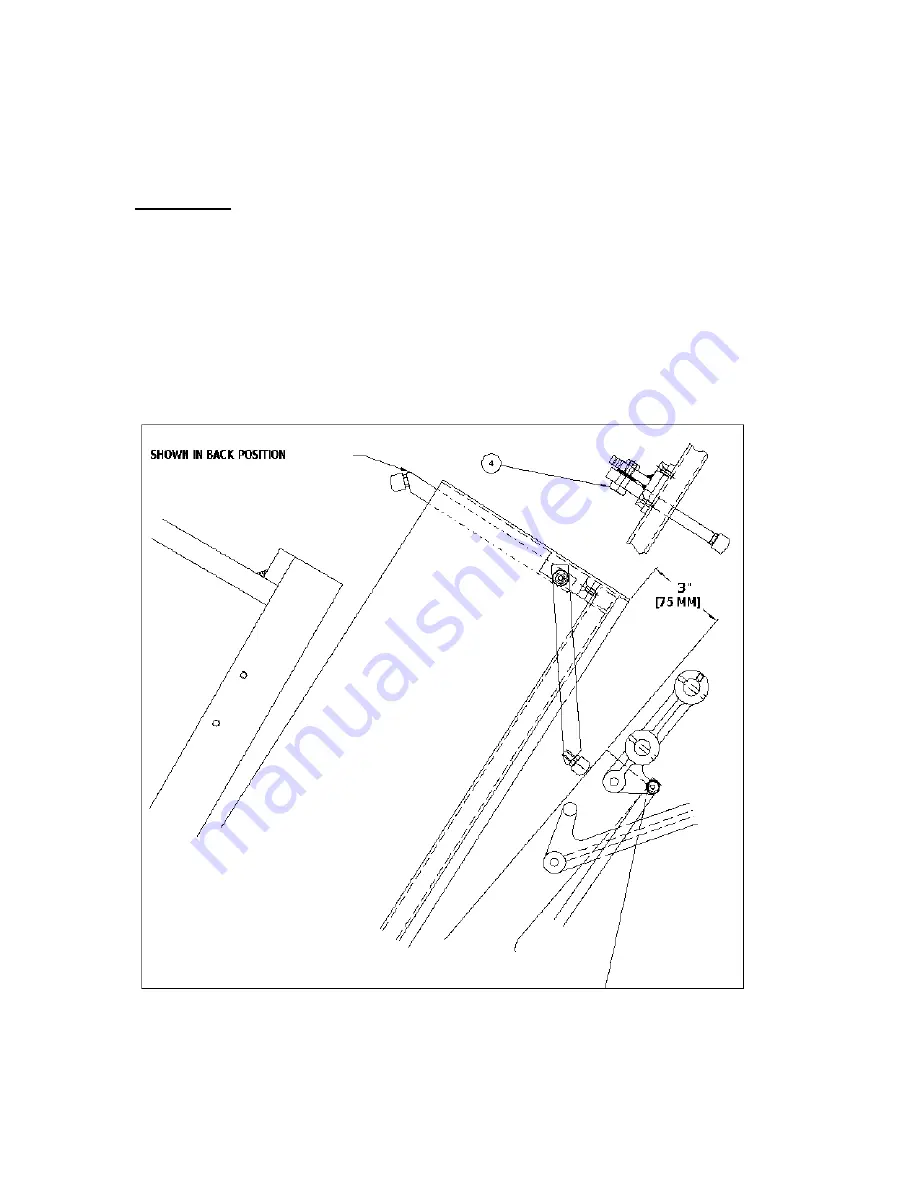

Safety Test Trip

The auxiliary safety test trip is a device to measure the acceptable distance between the platen and the die mounting

surface after the wrap around safety device is actuated. The test trip is installed by slipping the trip over the bolts, shown in the

assembly drawing. When the platen is cycled, the test trip contacts the top surface of the platen, causing the tripped wrap around

safety device to stop the press. To run the test, the press should be operating at its highest speed, to ensure that the requirement

for the minimum remaining distance is met at

all

operating speeds. After the platen strikes the removable test trip, the remaining

distance should be no less than 100mm between the platen and the die-mounting surface.

The 1996 safety standard states that

operators MUST run this test before regular operation every day to guarantee the proper working condition of the safety

device and braking system.

Return the safety test trip to back position after successful completion of the test for normal

operation of the machine. Below is a diagram of the proper test procedure.

Instruction Manual - 19" x 25"

Summary of Contents for VALUE LINE

Page 23: ...Page Instruction Manual 19 x 25 ...

Page 25: ... 25 25 Instruction Manual 19 x 25 ...

Page 27: ... 27 27 Instruction Manual 19 x 25 ...

Page 29: ... 29 29 Instruction Manual 19 x 25 ...

Page 31: ... 31 31 Instruction Manual 19 x 25 ...

Page 33: ...Page Instruction Manual 19 x 25 ...

Page 35: ... 35 35 Instruction Manual 19 x 25 ...

Page 37: ... 37 37 Instruction Manual 19 x 25 ...

Page 39: ...Page Instruction Manual 19 x 25 ...

Page 41: ...Page Instruction Manual 19 x 25 ...

Page 43: ... 43 43 Instruction Manual 19 x 25 ...