33

DIAGNOSIS

WARNING:

Make sure there are no fuel leaks before going any further. Clean

up any spills and always work in a well-ventilated area.

WARNING:

To avoid any electrical injuries always replace any broken wires

before proceeding.

WARNING:

The bilge can accumulate explosive fumes. The bilge blower will

evacuate the fumes. The bilge blower must be run for a minimum of 10 minutes

prior to cranking the engine.

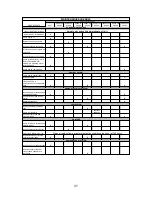

A. Engine Does Not Crank

Engine Does Not Crank

Check all fuses and relays

Check electrical leads – something may be loose or disconnected.

Check battery cables – adjust any loose connections and clean any corrosion.

Check battery charge

Refer to Pre-Operational checklist for further checks.

Engine Will Crank Intermittently

Having to turn the key to START several times. Check the ignition switch for loose,

corroded, disconnected or broken wires. Tighten or replace as necessary.

When The Engine Makes A Stuttering Or Chattering Noise.

Check the battery cables for loose connections

Check battery charge – charge if necessary

Check the starter motor and solenoid switch for loose or disconnected wires. Check

ground connections for loose, corroded, disconnect or broken wires.

If all electrical connections have been checked for loose connections, corrosion, broken

wires and disconnected wires and after you have reviewed and performed the

Operational Instructions, contact your service dealer.

Summary of Contents for KODIAK MARINE

Page 2: ...2...

Page 13: ...13 Component Identification...