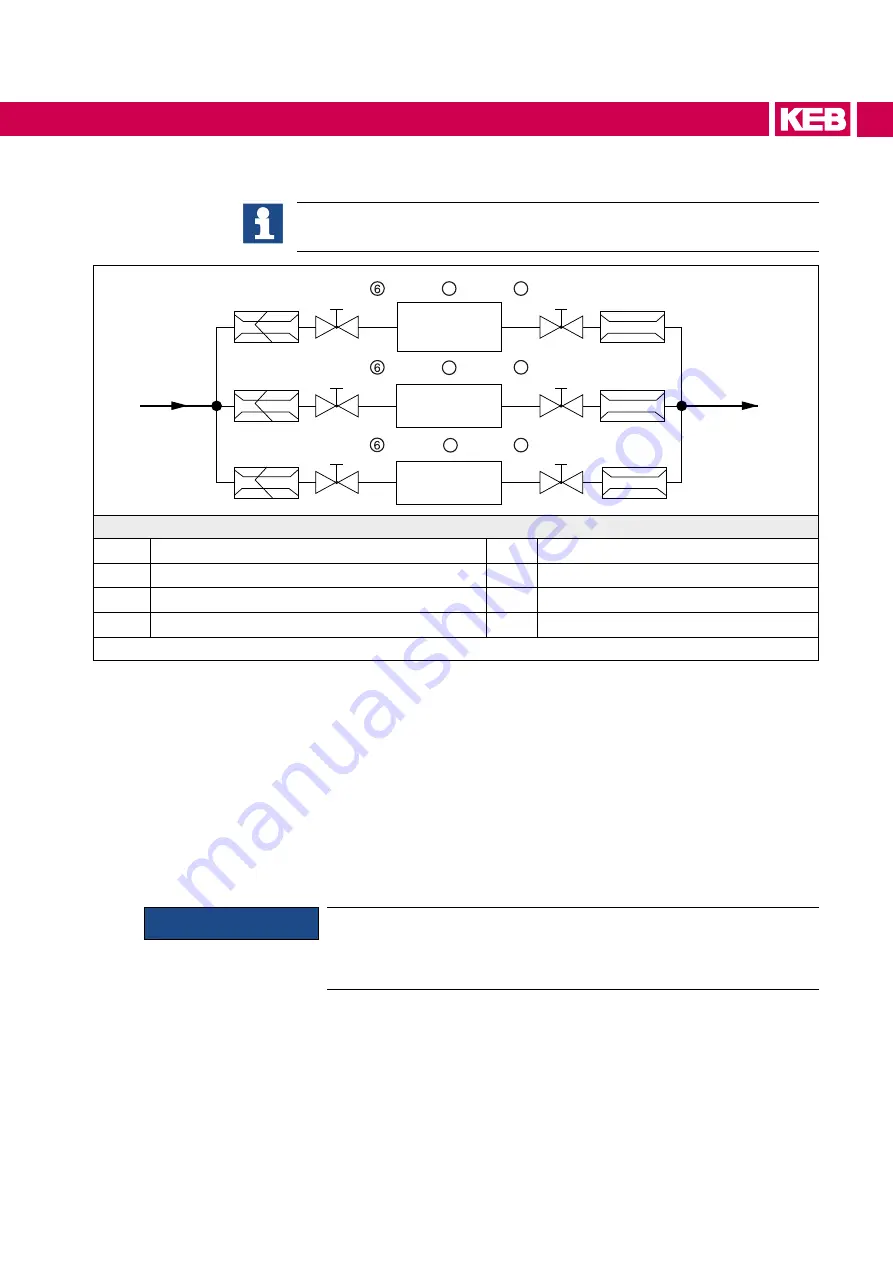

10.1.5.4 Connection scheme for a cooling circuit (parallel connection)

This connection scheme is only an installation proposal and does not replace

professional planning and execution!

①

➃

➄

②

③

②

①

②

③

②

①

②

②

Master

Slave

Slave

③

7

7

7

8

8

8

1/2“

1/2“

1/2“

1/2“

1/2“

1/2“

3/4“

3/4“

Legend

①

Flow limiter 10...40 l/min

⑤

Return flow entire system

②

Ball valve/stop valve

⑥

Precharging drive converter

③

Flow switch (e.g. Sika VH / VK)

⑦

Return flow drive converter

④

Pre-run entire system

⑧

Drive converter

Figure 30: Connection scheme for a cooling circuit

The connection of the coolant circuit to the drive converter system as a parallel execu-

tion is also possible in the rated operation and mandatory for special applications.

It should be noted that the use of flow controller and a temperature monitoring is manda

-

tory required. The cooling flow must always be started before starting the COMBIVERT.

Other elements in the cooling circuit such as pumps, shut-off valves, ventilation etc.

must be attached according to the cooling system and the local conditions.

The total volume flow depends on the specified heat power dissipation of the drive

converter system (see technical data). The data apply for rated operation. Special ap-

plications on request. The relationships between heat power dissipation, flow and tem

-

perature difference are shown in the diagram

„Volume flow in dependence of the heat

power dissipation and temperature difference“

NOTICE

The maximum temperature difference (ΔT) between pre-run and return

flow may not exceed 7K. If the volume flow (above 30 l/min per mod

-

ule) is selected too large, increases the risk of erosion in the liquid

cooler.

10.1.6 Decommissioning

The cooling circuit must be completely empty if a unit shall be switched off for a longer

period. The cooling circuit must be blown out additionally with compressed air at tem-

peratures below 0°C.

69

COOLING SySTEM

Summary of Contents for COMBIVERT F5 Series

Page 2: ......