4 | Connection of the control

KEB Automation KG

16

ma_dr_f6-cu-a-inst-20118593_en

4 Connection of the control

Observe the following instructions to avoid malfunctions!

• Install control cables and power cables separately (approx. 10…20 cm distance);

Lay crossings in a right angle.

• In case of inductive load on the relay outputs a protective wiring must be

provided (e.g. free-wheeling diode).

• Electro magnetic interferences can be prevented by the following measures:

– Always use twisted and shielded cables for analog control lines. Connect

the shield at one side at the signal source.

– Twist digital control cables. Up from 3 m a shield may be required. In this

case connect the shield at both ends.

– Connect the shield of the brake and temperature monitoring together with

the motor shield. Leave the inner shields longer in order to avoid interfer-

ence coupling or decoupling (the latter during temperature measurement)

as far as possible.

The terminals of the control terminal block, enocder inputs and communication in-

terface are securely isolated in accordance with

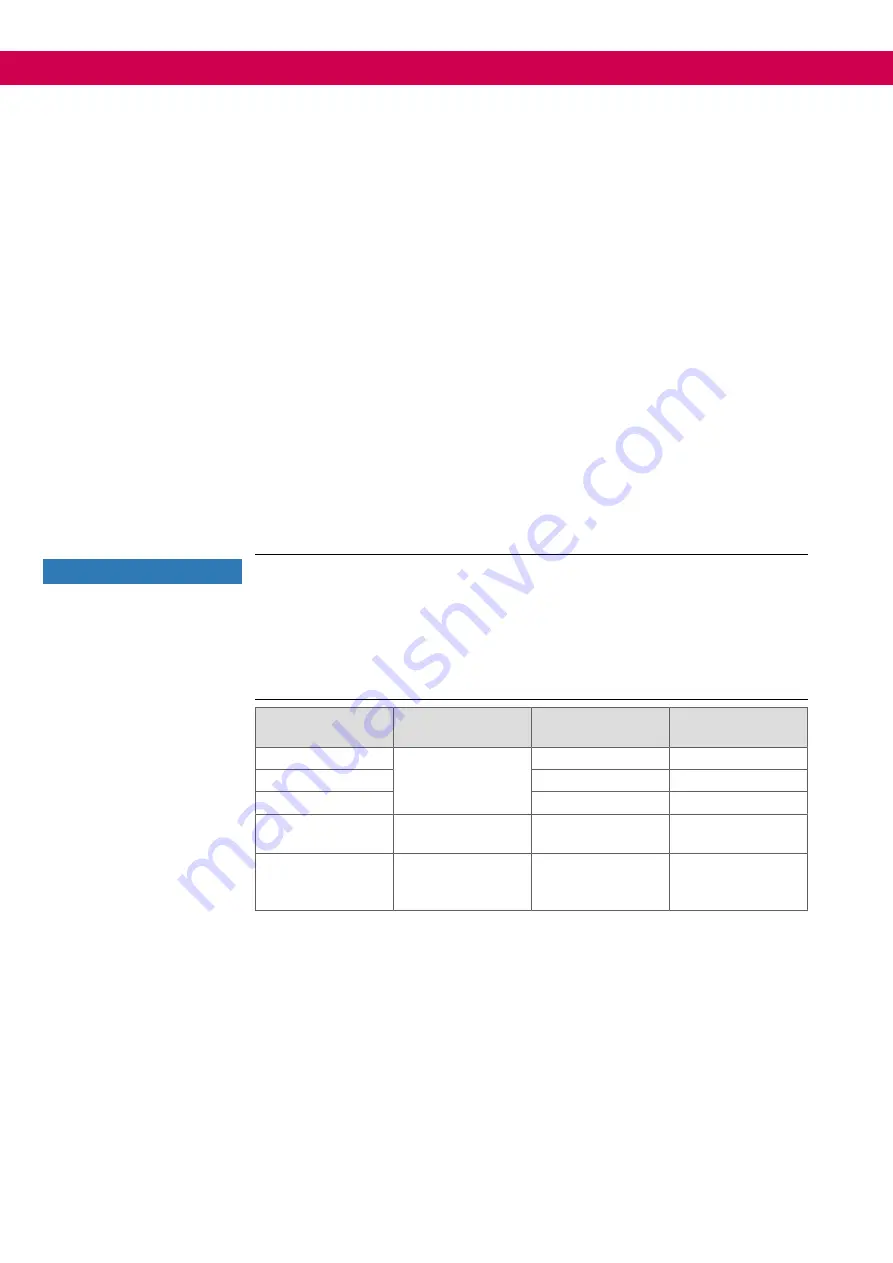

4.1 Assembly of wires

ACHTUNG

Loose and slack cable connections!

Malfunctions due to loose contacts.

a) Observe metal sleeve length and stripping length according to table.

b) Use a suitable pressing tool.

c) Make sure that all wires are inserted into the wire-end sleeve.

d) After inserting the cable into the terminal, check that it is firmly seated.

Cross-section

Wire-end ferrule

Metal sleeve

length

Stripping length

0.5 mm²

with plastic collars

10 mm

12 mm

0.75 mm²

12 mm

14 mm

1.0 mm²

12 mm

15 mm

1.5 mm²

without plastic col-

lars

10 mm

10 mm

0.2…1.5 mm²

ein- oder

feindrähtig

without wire-end

ferrule

-

10…12 mm

Tab. 8:

Wire-end ferrules and stripping length