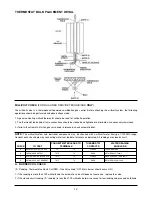

B. THERMOPILE OUTPUT CHECK

(“B” Reading. Thermostat contacts OPEN - Main burner

OFF.)

1. Thermopile system - 325 millivolts minimum. If the mini-

mum millivolt reading is not obtainable, readjust ther-

mopile for maximum millivolt output. If millivolt reading is

still below minimum specified, replace thermopile.

C. THERMOSTAT RESISTANCE CHECK

(“C” Reading. Thermostat contacts CLOSED - Gas valve

knob “ON”. Main burner should be ON.)

1. If the “C” reading is above 80 millivolts, the resistance in

the system is excessive and must be reduced. To correct:

a. Clean and tighten thermostat leads and connections.

b. Shorten or replace thermostat lead wires.

c. Cycle thermostat rapidly (manually turn dial) to clean

contacts.

D. AUTOMATIC PILOT DROPOUT CHECK

1. Hold gas valve knob depressed in pilot position until max-

imum output is observed. Then extinguish pilot and

observe meter.

2. Dropout of automatic pilot magnet (sound should be audi-

ble) should occur between

120

millivolts and

30

millivolts. If

dropout occurs outside these limits, change the valve.

MILLIVOLT CONTROL VALVE

To check Resistance of the gas valve, connect one wire

to the valve as shown.

1.

Resistance between the THTP & TH terminals

must be 11.5

⍀

±0.2

⍀

2.

Resistance between the THTP & TP terminals

must be 10.0

⍀

±0.2

⍀

If resistance is outside of specifications listed, the gas

valve must be replaced.

BEFORE REPLACING THERMOPILE CHECK

MILLIVOLT READINGS

THERMOPILE READINGS

With all wires connected, with the pilot on and burners

off, the thermopile reading at the TP&THTP terminals

should be ~325mv. With the burners on, the millvolt

reading should be ~200mv.

WARNING AND OPERATING PLATES

All warning and operating plates on the Keating MIRA-

CLEAN

®

Griddle should be in place at all times. If

plates are damaged or lost, replace them immediately.

13

Summary of Contents for SERIES 2000

Page 17: ......