9

1. Timed current limit "TCL": In this mode the drive will turn off after being in current limit

for a preset time. The time period is adjustable with the TCL trimpot from 0.5-15

seconds and is factory set for approximately seven (7) seconds.

TCL provides

electronic motor overload protection.

Application Note:

After the control times out in TCL, it can be reset using the Start

Switch by setting the switch to the "STOP" position and then to "START," or by

disconnecting and reconnecting the AC line. If the Start Switch is jumpered out, the

control can be restarted after timing out in TCL, by disconnecting and reconnecting the

AC line. Note, the Overload lamp will remain lighted until the control is reset.

2. Non-Timed Current Limit "NTCL": In this mode the drive will reach the preset current

limit during overload and stay at that level until a fuse blows or the drive is manually

turned off. If non-timed CL operation is desired, move jumper J5 from the factory set

"TCL" position to the "NTCL" position. The NTCL position must be used when

operating in the Torque Mode. See section II, A on page 5.

F. J6 – Tach-generator voltage –

(Note: Selection of this jumper

position is not required if tach-generator feedback is not used.) If

tach-generator feedback is used, select the J6 position (

7V

, 20/30V,

50V) which corresponds to the tach-generator voltage in

Volts/1000

RPM

. The selection of J6 position is based on a maximum motor

speed of 1800 RPM. If other than standard tach-generator voltages

and motor speeds are used, an external resistor (RT) may be used

(1/2 watt rating).

1. Install resistor (RT) in series with either tach-generator lead.

2. Place J6 in "7V" position.

3. Calculate the value of (RT) as follows:

RT = [(1.64 x VT x S) - 20,000] ohms

VT = Tach Voltage in Volts/1000 RPM

{

S = Base speed of motor in RPM

Note: For tach-generator feedback, Jumper J3 must be in the "T" position.

G. J7 – Signal Input Voltage –

The output of this control is normally controlled with the main

potentiometer. However, an

Isolated

analog voltage may also be used in place of a

potentiometer. The control can be scaled for either a 0-5VDC or 0-

10VDC by placing J7 in the appropriate position "5V" or

"10V"

. The

scaling can be further adjusted with the "Max" trimpot. See section IV,

F 2, on page 12 for wiring information.

Note: If an

Isolated

input signal is not available an accessory Signal Isolator Model KBSI-

240D (KB P/N-9431) can be installed. The KBSI-240D accepts a wide range of signal voltage

and current. An Installation Kit containing Auto/Man Switch and required wiring is also

available (P/N 9377).

III. MOUNTING

Mount the control in a vertical position on a flat surface. Be sure to leave enough room below

the bottom of the control to allow for the AC line and motor connections. Although the control

is designed for outdoor and washdown use, care should be taken to avoid extremely

hazardous locations where physical damage can occur.

Note: Do not use this control in

an explosion proof application.

If the control is mounted in a closed, unventilated cabinet,

remember to allow for proper heat dissipation. If full rating is required, a minimum enclosure

size of 12" W x 24" H x 12" D should be used.

Front Cover - The KBPC case is designed with a hinge so that when the front cover is open,

all wiring stays intact. To open the cover, the four cover screws must be loosened, so they

no longer are engaged in the case bottom. Note that these screws are captive and the front

cover holes are threaded. After mounting and wiring, close the front cover, making sure all

wires are contained within the enclosure and the gasket is in place around the cover lip.

Tighten all four cover screws so that the gasket is slightly compressed.

Do not overtighten.

50V

20/30V

7V

J6

10V

Summary of Contents for KBPC-240D

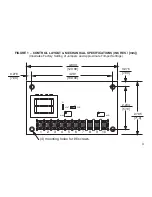

Page 6: ...3 FIG 1 CONTROL LAYOUT Illustrates Factory Setting of Jumpers and Approximate Trimpot Settings...

Page 7: ...4 INCHES mm FIG 2 MECHANICAL SPECIFICATIONS TM TM...

Page 20: ...20 FIG 17 CONNECTION DIAGRAMS FOR KBPC 240D WITH KBSI 240D SIGNAL ISOLATOR...

Page 36: ...NOTES 12...

Page 37: ...NOTES 13...