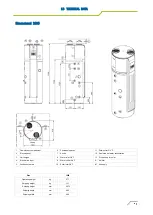

Coil

Accidental contact with the exchanger flaps can cause injuries

from cut: use protective gloves.

The coil must allow maximum thermal exchange, therefore, the

surface must be clear from dirt and scaling.

Clean the air inlet side.

Use a soft brush or aspirator.

Check the aluminium flaps have not been damaged or folded,

otherwise will be from "comb" the coil for excellent air flow.

( contact an authorised after-sales assistance centre )

Safety valve

The safety valves must be checked regularly.

Almost all losses are caused by impurities deposited inside the

valve.

It’s normal if some water drops from the hole of saftey valve

during operation. But, if there is a great amount of water, call

your service agent for instructions

If water doesn't flow freely when operating the handle, replace

safety valve with a new one

Nota

Please beware of burn, beware of the hot water from the

val-ve.

To clean the valve:

Manually open the valve

Turn the knob as indicated by the arrow on the knob itself

Expansion tank

Check the expansion vessel charge (at least once a year).

First check that the expansion vessel is totally drained of water.

If you necessary load with nitrogen, take care that the pressure

does not exceed the value indicated on the label.

Structure

Check the condition of the structure parts .

Paint so as to eliminate or reduce oxidation where needed.

Check that the paneling is correctly fastened. Poor fastening may

give rise to malfunctions and abnormal noise and vibration .

Restart after a long term stop

When the unit is restarted after a long term stop (included trail

running), it is normal that outlet water is unclean. Keep the tap

on and the water will be clean soon.

11 MAINTENANCE