2

Electric Dispenser Hoist EWL 2, 3, 4

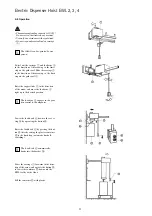

A 1.2 Important information

The instructions for use should be

read by the user before starting up the

unit for the first time, in order to avoid

incorrect operation and other damage. If

other language versions are required, please

request these from your responsible KaVo

agent. Duplication and distribution of the

instructions for use (IU) require KaVo's

prior consent.

All technical data, information and proper-

ties of the product described in the IU cor-

respond to the state on going to press.

Modifications and improvements to the

product as a result of new technical devel-

opments are possible.

This does not imply any right to retrofitting

of existing units.

KaVo assumes no responsibility for damage

arising through:

• external influences (poor quality of the

media or inadequate installation)

• use of incorrect information

• improper use

• improperly performed repairs.

Repair and maintenance work - apart from

the activities described in these instructions

for use - may be performed only by quali-

fied technical personnel.

In the event of modifications by third par-

ties, the approvals become null and void.

KaVo recommends using only original

spare parts for operation and for repair.

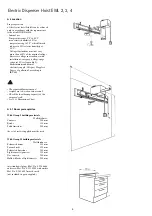

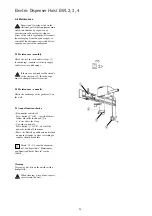

A 1.3 Precautions

Safe operation and protection of the unit

are ensured only through proper use in

accordance with the instructions for use and

using the tools approved for the purpose.

The following should also be observed:

• the work safety regulations,

• the accident prevention regulations.

In accordance with these conditions it is the

duty of the user:

• to use only flawless working materials,

• to observe correct usage and applications,

• at no time to exceed the maximum

carrying capacity,

• to ensure that nobody finds themselves

under the hoist or the mobile carrier when

in operation,

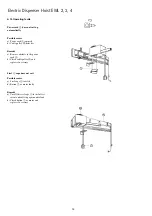

If the unit is not in operational condition as

prescribed by regulations, or improperly

used , for example:

• for the transportation of inappropriate

loads,

this can lead to the following consequences:

• loosening of wall fixtures

• breakage of the steel rope

• damage to the hoist arm, the guide rollers,

the motor or the drive movement.

• Safety features must not be bridged or

bypassed.

• Danger notices on the product are to be

observed.

• Other mechanical dangers are not to be

ruled out.

• Silolift to be operated by only one person.

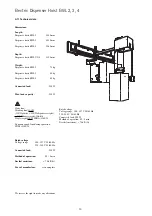

A 1 User information

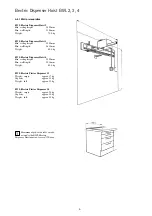

A 1.1 Meaning of the pictograms

Situations where failure to follow the

instructions may lead to danger,

damage to material or operating faults.

Important information for operator

and engineer.

Automatic mode

Automatic sequence

Close, screw in,

fasten, etc.

Open, release, loosen

+ more, higher

- less, lower

• Continuous operation

Time, time sequence

Disconnect mains plug