Operating Manual

10

Original Operating Manual

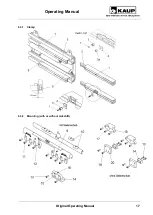

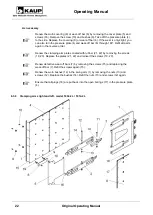

Hoist the attachment at the positions indicated (1).

Demount the lower hooks (2).

Mount the attachment on the fork carriage of the lift truck (3).

Check that the attachment is correctly seated in the centre lock (4).

Mount the lower hooks (2), tightening the screws (5) with a torque of 190 Nm.

Connect the hose lines (6) to the hydraulic connectors on the lift truck.

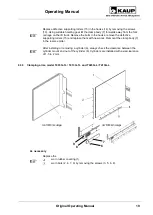

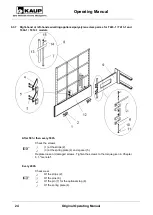

Trucks equipped with attachments which hold the load by power (e.g. paper clamp) shall

feature control(s) with a secondary action to prevent unintentional release of the load. Also

take note in this respect of the operating instruction of the lift truck.

Before initial operation, check the functions and the identification of the attachment with the

movement directions of the operating elements (operating lever, joystick, etc.).

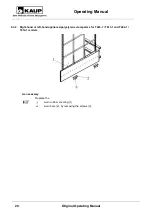

Mount the residual carrying capacity notice and identification of the operating elements (if

not already present) of the combination of lift truck/attached equipment on the lift truck.