WTC 600 LP / MP

8

Maintenance and Care

Version 06/05

• Before screwing on the filter bowl, check the

sealing ring (39) for damage.

• Screw on the filter bowl and tighten with the fil-

ter wrench.

• Open the untreated water supply again and

start the system with the main switch.

3.2.5

Fine Adjustment of the Operating

Pressures

(1)

Flow of drinking water has decreased

from _____ to _____ l/h

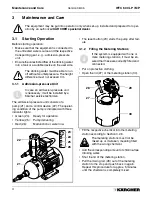

Read off the amount of drinking water at the flow

meter (42) and compare with the value taken

when starting operation (see operational start-up

record).

• Slowly shut the pressure control valve (14) in

clockwise direction until the desired amount is

almost reached at the flow meter (42).

• Slowly shut the concentrate control valve (13)

in clockwise direction until the respective set

value is reached on both flow meters for con-

centrate (43) and drinking water (42).

Notice: The quantity of concentrate will in-

crease. This is correct.

• Carry out a readjustment on both valve levers,

if required.

(2)

Conducting capacity of the drinking

water has increased from _____

to _____ µS/cm

On the display of the control panel (10), read the

current drinking water conductance value and

compare with the value taken when starting oper-

ation (see operational start-up record).

• Open the concentrate control valve (13) in coun-

terclockwise direction in small steps until the con-

ductance capacity has reached the set value.

• Shut the pressure control valve (14) in clock-

wise direction in small steps until the drinking

water amount in the viewing glass (42) has

reached the set value.

In case of alterations to the system

adjustments, the following values must

not be exceeded under any circum-

stances:

• Pump pressure, max. 21 bar (MP) or

14 bar (LP)

• Drinking water amount, max. 650 l/h

• The concentrate amount must not ex-

ceed the operational start-up value

i

The system reacts somewhat time-

delayed to alterations of the regulation

valves. Therefore carry out the adjust-

ment at the pressure control valve (14)

and at the concentrate control valve

(13) only in small steps, and wait until

checking the respective effect.

If the flow of drinking water has de-

creased to _____ l/h , the following fine

adjustment is to be carried out.

If the fine adjustment does not lead to

an increase in the drinking water flow,

the Kärcher Service must be con-

tacted.

i

Small increases of the drinking water

conducting capacity do not influence

the drinking water quality.

If the drinking water conductance value

has increased to _____ µS/cm, the follow-

ing fine adjustment is to be carried out.

If the fine adjustment does not lead to a

decrease of the drinking water con-

ductance value, the Kärcher Service

must be contacted.

42

11

13

14

10

12

43