WTC 600 LP / MP

3

Safety Notes

Version 06/05

Contents

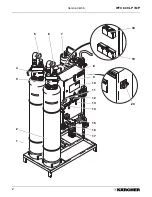

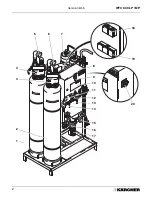

Equipment Components

1 Sand filter

2 Activated carbon filter

3 Control, activated carbon filter

4 Control, sand filter

5 Manometer, sand filter supply pressure

6 Manometer, activated carbon filter supply

pressure

7 RO filter unit

8 Switch box

9 Operating mode switch

10 Control panel

11 Manometer, pump pressure

12 Manometer, concentrate pressure

13 Concentrate control valve

14 Pressure control valve

15 Manometer, fine filter supply pressure

16 Manometer, fine filter output pressure

17 Fine filter unit

18 Power outlets, sand and activated carbon

filter

19 Power outlets (3x) for metering stations

20 Main switch

1

Safety Notes

Drinking Water

❑

Drinking water quality is ensured only when the

equipment is controlled within the scheduled

periods. Observe the given control intervals.

❑

Have the drinking water quality checked in reg-

ular intervals; the valid drinking water regula-

tions are to be observed.

Chemicals

❑

Wear acid-resistant protective clothing (gog-

gles and gloves).

❑

Store chemicals cool and dry, however, not

below 5 °C.

❑

Keep chemicals at locations not accessible for

children.

❑

Ensure good room ventilation and provide a

washing facility.

❑

Have eye wash bottle readily available.

Electrical Equipment

❑

Work on the electrical equipment is to be car-

ried out only by skilled persons for electrical

work.

❑

Never touch damaged or cut through mains

cables; pull the mains plug immediately, as

required.

❑

Never operate the equipment with a damaged

cable.

2

Intended Use

The equipment is used for conditioning of surface

water, well water and river water.

Depending on the untreated water quality,

the modular set-up enables secure separation

of turbid materials, water hardeners, salts and

bacteria/virus.

1

Safety Notes...........................................3

2

Intended Use ..........................................3

3

Maintenance and Care ...........................4

3.1

Starting Operation ..................................4

3.1.1 Admission-pressure Unit ........................4

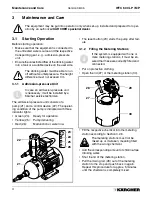

3.1.2 Filling the Metering Stations ...................4

3.1.3 Switching On the Equipment ..................5

3.1.4 Operating Indicators ...............................5

3.2

During Operation ....................................5

3.2.1 Control and Corrective Action Intervals ..5

3.2.2 Sand and Activated Carbon Filter ..........6

3.2.3 Bleeding the Metering Pump ..................6

3.2.4 Replacing the Fine Filter ........................7

3.2.5 Fine Adjustment of the Operating Pressu-

res

...............................................................7

3.2.6 Mixing the Chemicals .............................8

3.3

Switching Off the Equipment ..................9

4

Consumption Materials...........................9

5

Malfunctions .........................................10

6

Technical Data .....................................11

7

EU Declaration of Conformity ...............12

Safe operation of the equipment is

possible only when the operating in-

structions and safety notes are read

completely, and the instructions con-

tained therein are strictly followed.