8.780-013.0

• Xpert-HD/DD • Rev. 10/09

OPERATOR’S MANUAL

PRESSURE WASHER

10

STEP 8:

Turn the engine switch to "On" position.

On Briggs engines, move the throttle lever to "Fast"

position, shown on the engine as a rabbit.

STEP 9: Pull the starter grip. If the engine fails to start

after 2 pulls, squeeze the trigger gun to release pres-

sure and repeat step. Return starter gently. After the

engine warms up enough to run smoothly, move choke

to run position and throttle to fast position.

CAUTION: Small engines may kick back. Do not

hold pull starter grip tightly in hand.

OPERATING INSTRUCTIONS

WARNING! Never replace

nozzles without engaging the

safety latch on the spray gun

trigger.

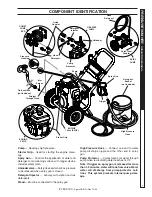

The five color-coded quick connect nozzles provide a wide array of

spray widths from 0° to 40° and are easily accessible when placed in the

convenient rubber nozzle holder, which is provided on the front of the

machine.

NOTE: For a more gentle rinse, select the white 40° or green 25° nozzle.

To scour the surface, select the yellow 15° or red 0° nozzle. To apply de-

tergent select the black nozzle.

NOzzLES

Safety

Latch

On-Off

Switch