2

【

2

】

MACHINE SPEED

2-1 Machine speed & direction in which the machine pulley runs

Refer to the table below for maximum and standard

speeds of the Series. To extend machine life, run

the machine approximately 15~20% below the

maximum speed for the first 200 hours of operation

(approx. 1 month). Then run the machine at the

standard speed. The machine pulley turns

clockwise as the handwheel does as seen from the

machine pulley.

2-2 Motor & belt

Motor : 3-phase, 2-pole, 400W clutch motor

Belt

: M type V belt

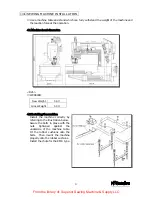

Select the proper motor pulley according to the

machine speed (refer to the motor pulley outer

diameter on the table below). Adjust where to

position the motor by pressing the finger onto the

middle of the belt so that 1~2cm deflection can be

obtained (see the illustration on the right).

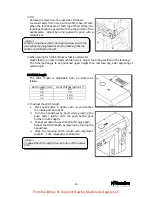

< Machine speed >

TYPE

MAXIMUM SPEED

STANDARD SPEED

WX8803 6000SPM

5500SPM

WX8803EMK 5000SPM

4500SPM

LX5801 6500SPM

6000SPM

< Motor pulley selection table >

Machine speed (SPM)

Motor pulley

outer diameter (mm)

50Hz

60Hz

80

3300

3900

90

3700

4400

100

4100

4900

110

4500

5400

120

5000

5900

130

5300

6400

140

5800

(6900)

150

6200

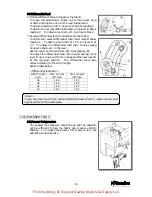

< Ref. Data >

1.

Seam Type JIS 602

,

605

,

401

,

408

2.

Noise Value ISO/DIS 10821 conformity

Machine speed

(SPM)

Average dB(A)

4500 74.7

5400 82.8

From the library of: Superior Sewing Machine & Supply LLC