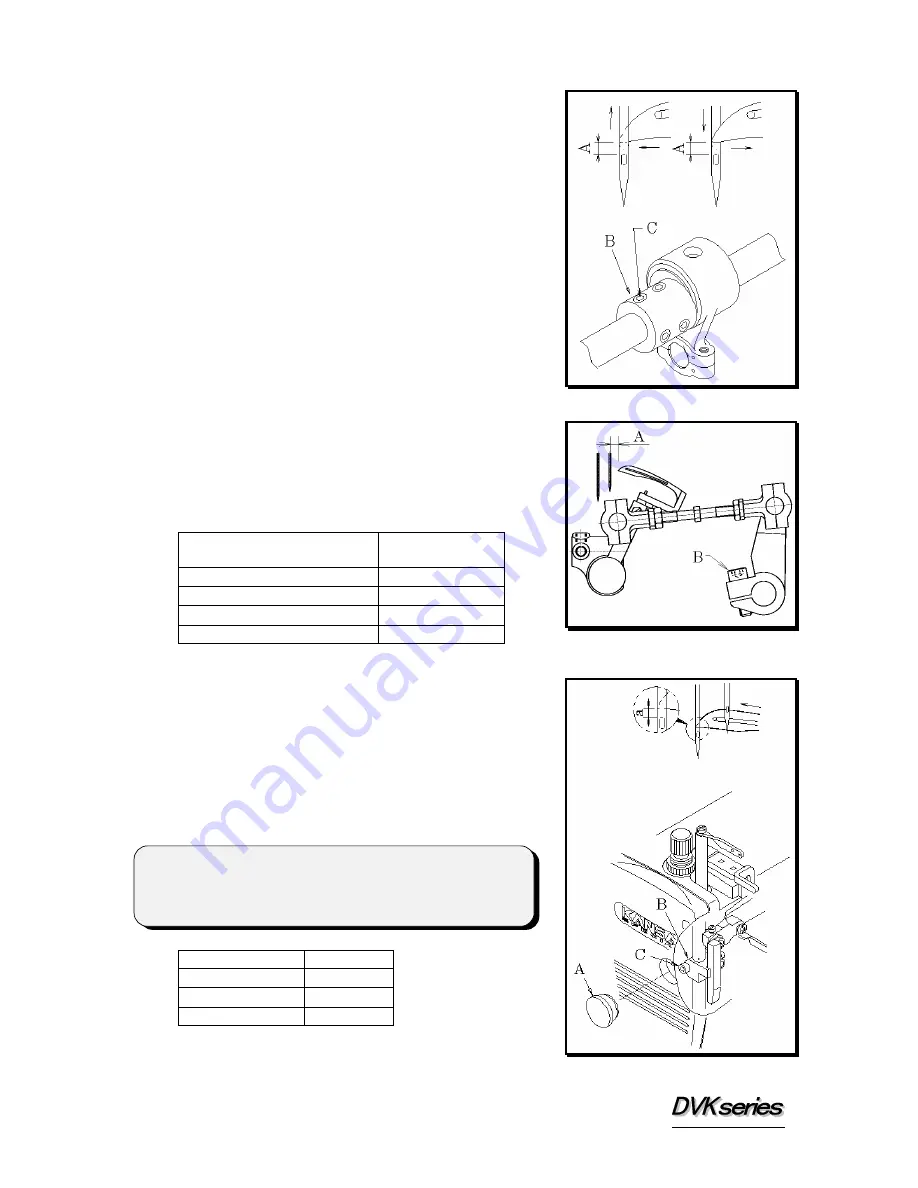

5-2 Looper left-to-right movement

When the point of the looper moves from the right/left

to the left/right, distance A from the top of the left

needle's eye to the point of the looper at the left side of

the left needle should be equal (see the illustration on

the right). To make this adjustment, remove the

machine cover, loosen three screws C on looper

eccentric B and then shift looper eccentric B by

turning the machine pulley while holding looper

eccentric B.

5-3 Looper setting distance

When the looper is at the extreme right end of its

travel, adjust distance A from the point of the looper

to the right side of the right needle. This distance

varies by model and/or gauge size (see the table below).

Adjustment is made by loosening screw B.

Model (gauge size)

Setting distance

A (mm)

P

,

PMD

,

MLH (1/8

,

5/32)

5.2

P

,

PMD

,

(3/16

,

7/32

,

1/4)

4.4

B

,

BK

,

PBK

4.0

EHD 5.0

5-4 Needle height

When the point of the looper has reached the left side

of the left needle with the machine pulley turned in

the operating direction, adjust distance a from the top

of the left needle's eye to the point of the looper on the

back side of the needle. This distance varies by

model and/or gauge size (see the table below).

The adjustment is that raise needle bar up or down by

remove rubber caps A and loosen the screw C.

Model A

(mm)

P

,

PMD

,

MLH

1.2~1.5

B

,

BK

,

PBK

0~0.5

EHD 2~2.5

< Note >

After the above adjustment is made, install the needle

plate and then check to make sure each needle drops

correctly into the center of the each needle drop hole.

6