Jaden Kanga Group

Page

Jaden Kanga – OPERATORS MANUAL

34

Hydraulic Pressure Settings

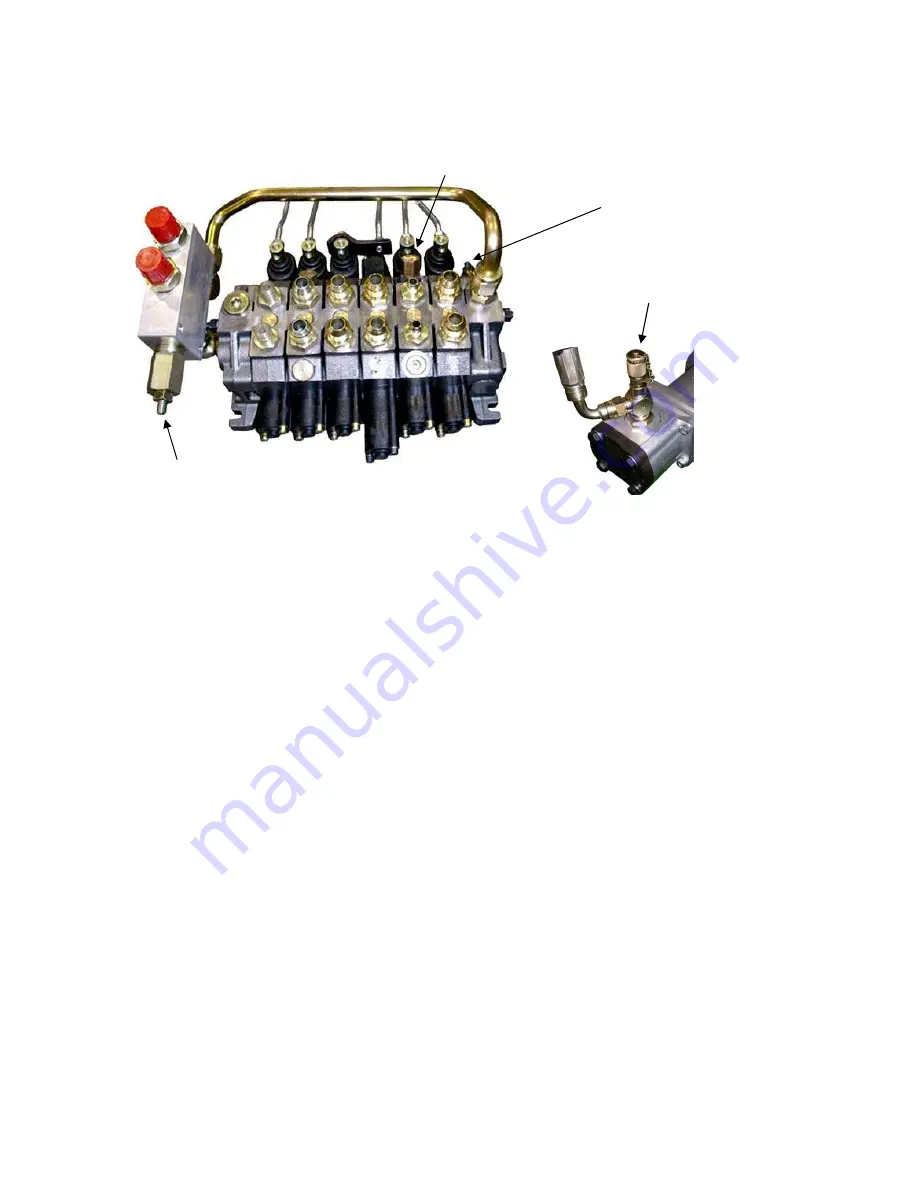

The hydraulic system has three pressure settings which have to be set as follows:

(2)

MAIN SYSTEM RELIEF

PRESSURE TEST POINT

(1)

OVERCENTRE VALVE

(3)

LIFT PRESSURE

Before any testing is carried out run the engine and hydraulic system to warm the hydraulic oil to 80°C ( 176°F ).

All pressure setting are performed with the engine running at full speed (3600 rpm).

OVER CENTRE VALVE

Connect an accurate pressure gauge with a range 0-300 bar ( 0-4300 PSI ) to the test point.

The pressure should be set at:

32 bar (460 PSI) for Series 5 machine

41 bar (600 PSI) for Series 6 machine

NOTE: If adjustment is required slacken off the lock nut and using a 5mm hex key wind in the screw to

increase the pressure or back off the screw to reduce the pressure. Retighten the lock nut when

adjustments are complete.

(2)

MAIN SYSTEM RELIEF PRESSURE

Connect an accurate pressure gauge with a range 0-300 bar ( 0-4300 PSI ) to the test point.

Check the pressure while pulling the tilt control lever at the end of the rams stroke.

The pressure should be set at 203 bar (2950 PSI) .

NOTE: If adjustment is necessary slacken off the lock nut and wind in the screw to increase the pressure

or back off the screw to reduce the pressure. Retighten the lock nut when adjustments are complete.

LIFT PRESSURE

Connect an accurate pressure gauge with a range 0-300 bar ( 0-4300 PSI ) to the test point.

Check the pressure while pulling the boom control lever at the end of the rams stroke

(boom fully

risen).

The pressure should be set at 165 bar (2400 PSI).

NOTE: If adjustment is necessary unscrew and remove the cap lock nut and wind in the screw using a

screw driver to increase the pressure or back off the screw to reduce the pressure. Refit

and tighten

the lock nut when adjustments are complete.

Summary of Contents for 5 Series

Page 14: ...Jaden Kanga Group Page Jaden Kanga OPERATORS MANUAL 14 SAFETY Summary ...

Page 17: ...Jaden Kanga Group Jaden Kanga OPERATORS MANUAL Page 17 TASK PLANNING FOR THE KANGA LOADER ...

Page 19: ...Jaden Kanga Group Jaden Kanga OPERATORS MANUAL Page 19 ...

Page 50: ...Jaden Kanga Group Page Jaden Kanga OPERATORS MANUAL 50 HYDRAULIC CONNECTIONS Series 6 ...

Page 51: ...Jaden Kanga Group Jaden Kanga OPERATORS MANUAL Page 51 HYDRAULIC CONNECTIONS Series 7 ...

Page 77: ...Jaden Kanga Group Jaden Kanga OPERATORS MANUAL Page 77 ...

Page 78: ...Jaden Kanga Group Page Jaden Kanga OPERATORS MANUAL 78 5 5 ...