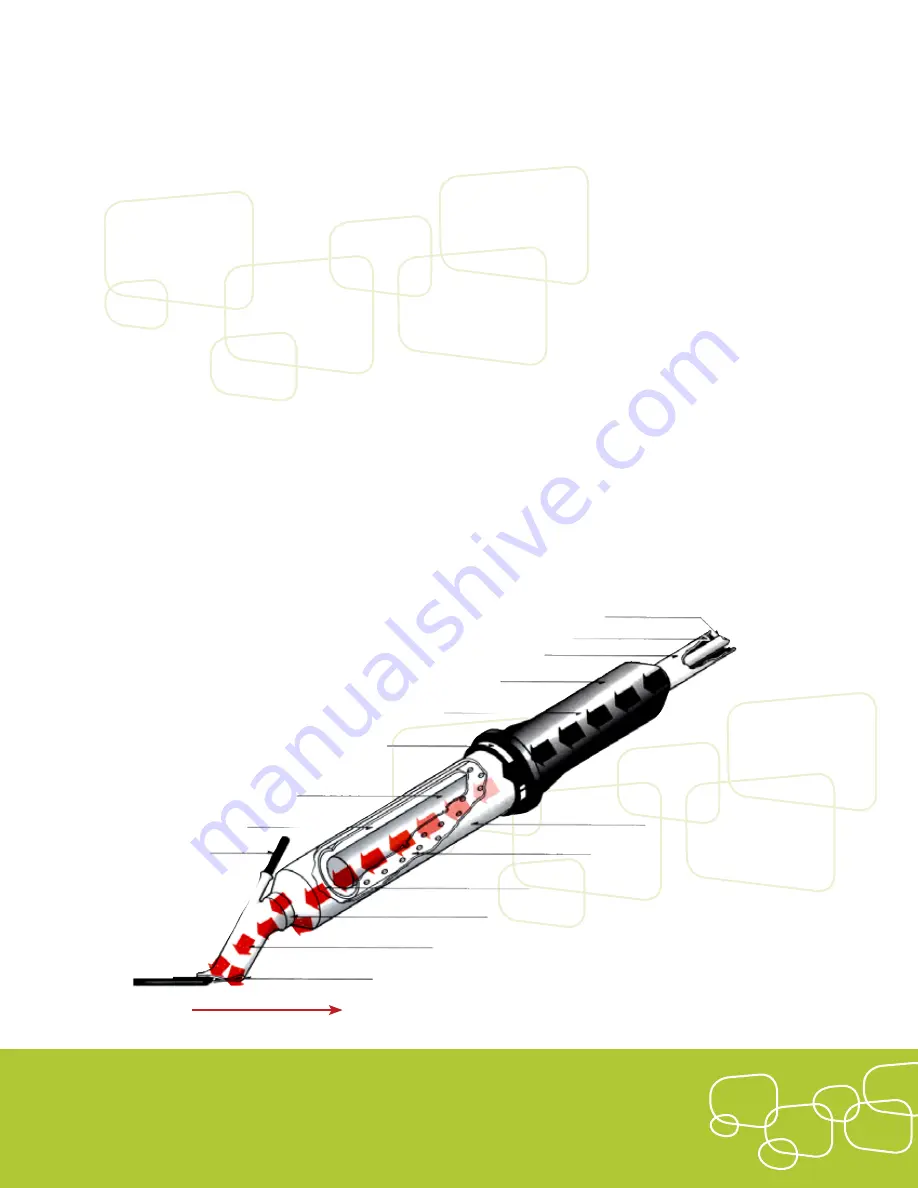

120 Volts AC

Compressed Air or Inert Gas

Air Hose

Air Cooled Handle

Cold Air

Spanner Nut

Stainless Steel Heating Element

Welding Rod

Heating Chamber

Direction

Preheat for Base Material

Welding Tip or Tool

Threaded Nozzle

Hot Air

Inner Barrel

Outer Barrel

3

TYPES OF KAMWELD PLASTIC WELDERS:

There are two basic types of Kamweld plastic welders. The

first operates on standard compressed air supply, available

in most shops, or on bottled inert gas. Models 41-HT, 42-TM,

43-HS and 44-A-W use compressed air. The second type

of welder is self-contained with a built-in air compressor.

Models 46-RW and 47-RW are self-contained units. Inert gas

CANNOT BE USED. These portable units are for use in the

field or in the shops, both indoors and outdoors.

WELDING TEMPERATURE:

Most thermoplastics are weldable between 572ºF and 752ºF

(300 ºC and 400 ºC) when hand welding, using the models

such as KR and KRL or hi-speed welding, using tips such as

the KS-1-8 or KS-2C. The temperature is closely controlled by

selecting the proper heating element and by changing the

amount of air or inert gas by flow.

Most thermoplastic materials such as PVC (Polyvinyl Chlo-

ride), PE (Polyethylene), PP (Polypropylene), PS (Polystyrene),

Acrylics, some blends of ABS (Acrylic-Butadiene, Styrene), PC

(Polycarbonates) and others can be welded. In welding PE

(Polyethylene) an inert gas (such as dry Nitrogen or Argon)

MUST be used. In most cases, it is not practical to weld mate-

rials any thinner than 1/8” thick, because of heat distortion.

In some cases, materials as thin as 1/18” can be welded if

supported underneath the joint while welding. Doing so will

prevent heat distortion.