KAIRAK

Page 11

- 11 -

IM-ES-REV 5-09-06.doc5-09-06

CONDENSING UNIT

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY

PARTS ON THE UNIT.

The condensing unit coil and filter must be cleaned regularly on self-contained models for

optimal performance. The operating environment will affect the required frequency of cleaning.

However, both should be cleaned a minimum of once every three months. Air must be able to

freely circulate through the condenser. Unit performance and operating efficiency are

significantly affected by the amount of air passing through the condenser. Condenser fins that

are clogged with dirt and debris greatly reduce required airflow.

Failure to keep the coil fins

and the air filter clean may cause premature compressor failure, which will not be

covered by warranty. (On models that contain filters, operating unit without filter will

void warranty).

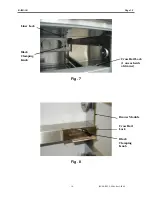

The condensing unit is located behind the louvered panel in the compressor compartment.

Remove louvered panel by pulling on the bottom then lifting up and out. Remove rear access

panel located in the back of unit. A phillips head screwdriver is required to remove rear access

panel. Carefully clean dirt and lint from the condenser coil using a vacuum cleaner or soft

brush; do not use a wire brush.

The filter is located behind the louvered panel, below the condensing unit in the compressor

compartment. Remove filter by carefully sliding out of the tracks. Carefully clean with vacuum

or rinse with hot water exercising care not to bend or damage filter frame. Replace filter by

carefully sliding it into the tracks. Replace louvered panel by installing top of panel into track and

pushing in the bottom so that the locking clips fit inside the opening. Replace rear access

panel. Reconnect electrical supply.

Replacement filters are available through Kairak Parts and Service Department at

714-870-8661.

EVAPORATOR COILS

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY

PARTS ON THE UNIT.

Evaporator coils should be cleaned every six (6) months for optimal performance.

The evaporator coils are located in the storage cabinet behind the coil can cover. With a phillips

head screwdriver, remove four screws and take off cover. Clean evaporator coils with a

vacuum cleaner or soft brush, do not use a wire brush. Replace coil can cover. Reconnect

electrical supply.