➤ Dispose of parts and materials contaminated with oil in accordance with environmental

protection regulations.

Start the machine and carry out a trial run

1. Close all access doors, replace and secure all removable panels.

2. Open the user's shut-off valve between the machine and the compressed air network.

3. Switch on the power supply and reset the maintenance interval counter.

4. Stop the machine after 10 minutes and visually check for leaks.

10.17 Refrigeration dryer maintenance

The refrigeration circuit is permanently sealed and needs no maintenance. Repairs may only be

carried out by certified personnel.

Material Compressed air for blowing out

Cleaning cloths

Vacuum cleaner

Spares as required

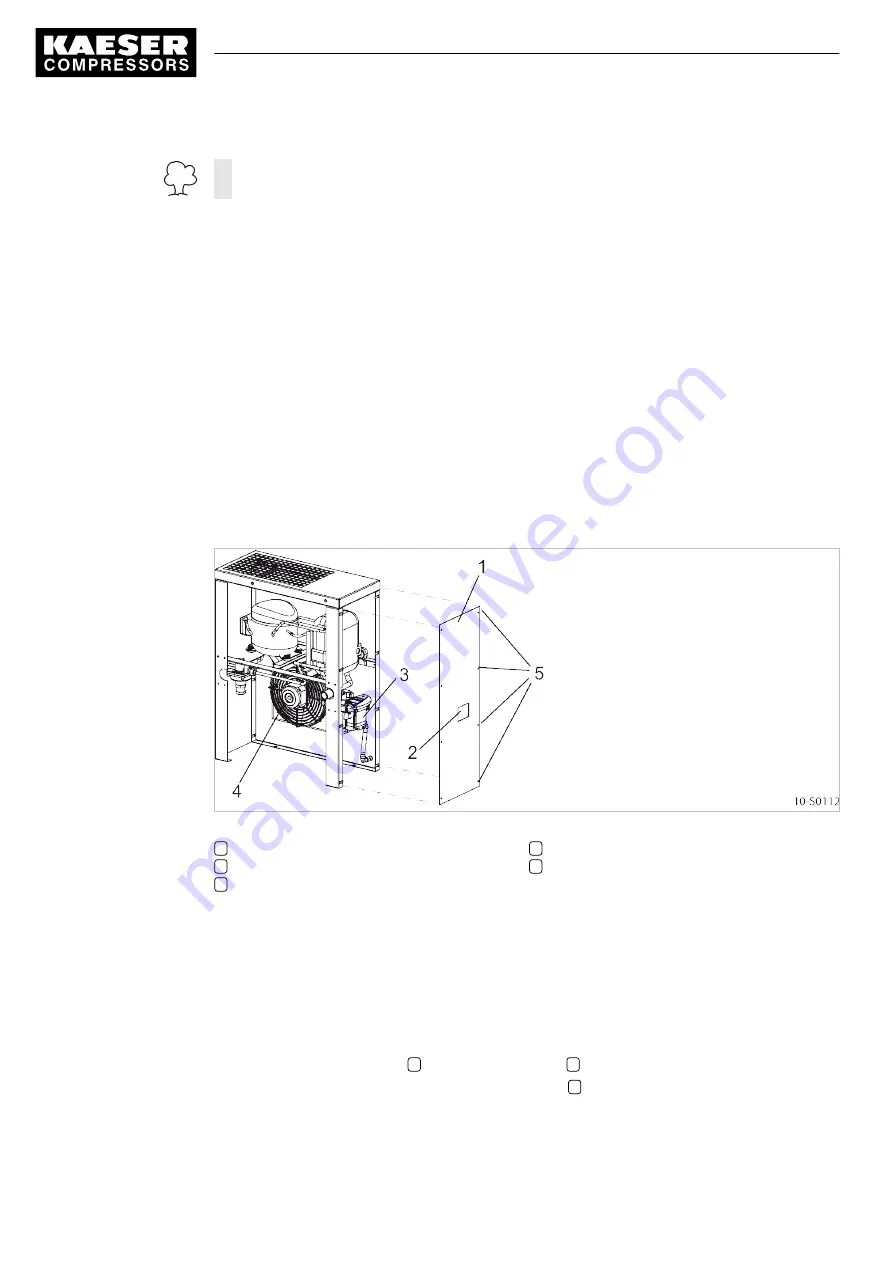

Fig. 37 Refrigeration dryer

1

Access panel

2

Viewing window: condensate drain

3

Condensate drain

4

Refrigerant condenser

5

Screw

➤ Check and clean the refrigerant condenser and condensate drain regularly as described below.

10.17.1 Cleaning the refrigerant condenser

Precondition The supply disconnecting device is switched off,

the device is locked off,

a check has been made that no voltage is present.

1. Undo the securing screws

5

and remove the panel

1

.

2. Use compressed air (<5 bar) to blow the condenser

4

through from inside to outside and then

vacuum up the dirt.

3. Replace the panel again.

10 Maintenance

10.17 Refrigeration dryer maintenance

72

Service manual Screw compressor

Aircenter SX 3/7.5 SIGMA CONTROL BASIC

Number: 9_6945 01USE