3-2

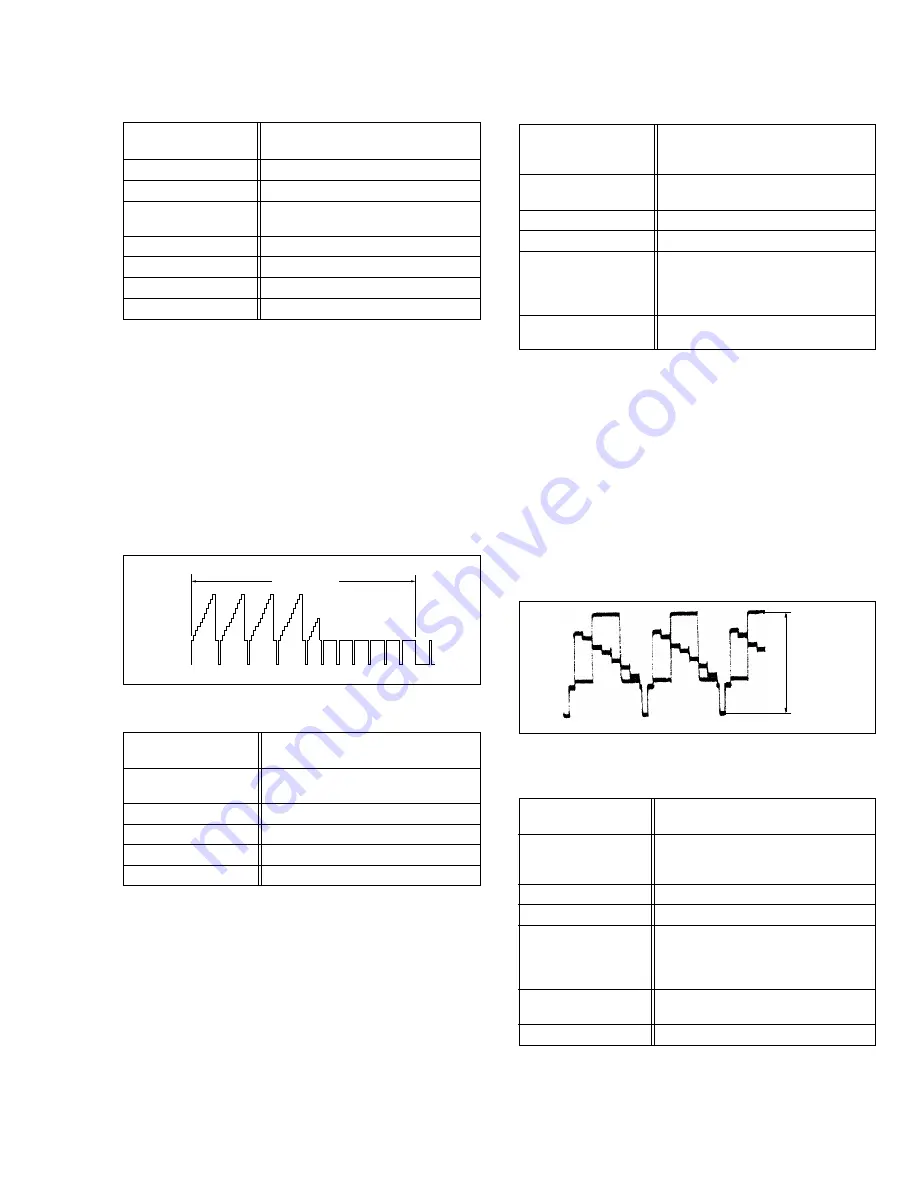

Fig. 3-2-1a Switching point

V.sync

Trigger point

Switching point

V. rate

3.2.2 Slow tracking preset

Signal

(A1)

• Ext. input

(A2)

• Color (colour) bar signal [PAL]

Mode

(B1)

• VHS SP

(B2)

• VHS LP

Measuring point

(D)

• TV-Monitor

Adjustment part

(F)

• Jig code “71“ or “72”

Specified value

(G)

• Minimum noise

Adjustment tool

(H)

• Jig RCU [PTU94023B]

(1) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(2) Set the VCR to the manual tracking mode.

(3) Set the VCR to the FWD slow (+1/6x) mode.

(4) Transmit the code (F) from the Jig RCU to adjust so that

the noise bar becomes the specified value (G) on the TV

monitor in the slow mode.

(5) Set the VCR to the Stop mode.

(6) Confirm that the noise bar is (G) on the TV monitor in

the slow mode.

(7) Repeat steps (3) to (6) in the REV slow (–1/6x) mode.

(8) Repeat steps (1) to (7) in the mode (B2).

Note:

•

For FWD slow (+1/6x) playback, transmit the code “08”

from the Jig RCU to enter the slow playback mode, and

transmit the code “D0” for REV slow (–1/6x) mode.

3.2

Servo circuit

3.2.1 Switching point

Signal

(A1)

•

Stairstep signal

(A2)

•

Alignment tape (SP,stairstep,PAL) MHPE

Mode

(B)

•

PB

Equipment

(C)

•

Oscilloscope

Measuring point

(D1)

•

VIDEO OUT terminal (75

Ø

terminated)

(D2)

•

TP106 (PB. FM)

External trigger

(E)

•

TP111 (D.FF)/slope : –

Adjustment part

(F)

•

Jig code “5A”

Specified value

(G)

•

7.5 ± 0.5H

Adjustment tool

(H)

•

Jig RCU [PTU94023B]

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D.FF (E) to observe

the VIDEO OUT waveform and V.PB FM waveform at the

measuring points (D1) and (D2).

(3) Set the VCR to the manual tracking mode.

(4) Adjust tracking so that the V.PB FM waveform becomes

maximum.

(5) Set the VCR to the Auto adjust mode by transmitting the

code (F) from the Jig RCU. When the VCR enters the

stop mode, the adjustment is completed.

(6) If the VCR enters the eject mode, repeat steps (1) to (5)

again.

(7) Play back the alignment tape (A2) again, confirm that the

switching point is the specified value (G).

Fig. 3-3-1a D/A level

(1) Insert the cassette tape (A3) to enter the mode (B).

(2) Observe the VIDEO OUT waveform at the measuring

point (D).

(3) Check the Y level value when the External S-input (Y/C

separated video signal).

(4) Switch the input signal to the External input (composite

video signal), and adjust the adjustment part (F) so that

the Y level becomes the same value observed in step

(3).

Note:

• The specified value (G) is just a reference value to be

obtained when the External S-Video (Y/C separated

video) signal is input. In actual adjustment, set it to

the value observed in step (3).

H. rate

Y level

3.3 Video circuit

3.3.1 D/A level

Signal

(A1)

•

Ext. S-input / Ext. input

(A2)

•

Color (colour) bar signal [PAL]

(A3)

•

S-VHS tape

Mode

(B)

•

S-VHS

•

EE

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

Y OUT terminal (75

Ø

terminated)

Adjustment part

(F)

•

VR1201 (D/A LEVEL ADJ)

[2D DIGITAL board]

•

VR1401 [D/A LEVEL ADJ]

[3D DIGITAL/2M board]

Specified value

(G)

•

1.00 ± 0.015 Vp-p (reference value)

(Note)

Signal

(A1)

•

Ext. input

(A2)

•

Color (colour) bar signal [PAL]

Mode

(B1)

•

EE

(B2)

•

S-VHS SP

(B3)

•

VHS SP

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

Y OUT terminal (75

Ø

terminated)

EVR mode

(F1)

•

Jig code “57”

EVR address

(F2)

•

A : 11

(F3)

•

Jig code “21”

(F4)

•

Jig code “18” or “19” (C/-)

Specified value

(G)

•

1.00 ± 0.05 Vp-p [2D DIGITAL board]

•

1.00 ± 0.03 Vp-p [3D DIGITAL/2M board]

Adjustment tool

(H)

•

Jig RCU [PTU94023B]

(1) Observe the Y OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(3) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

3.3.2 EE Y/PB Y (S-VHS/VHS) level