•

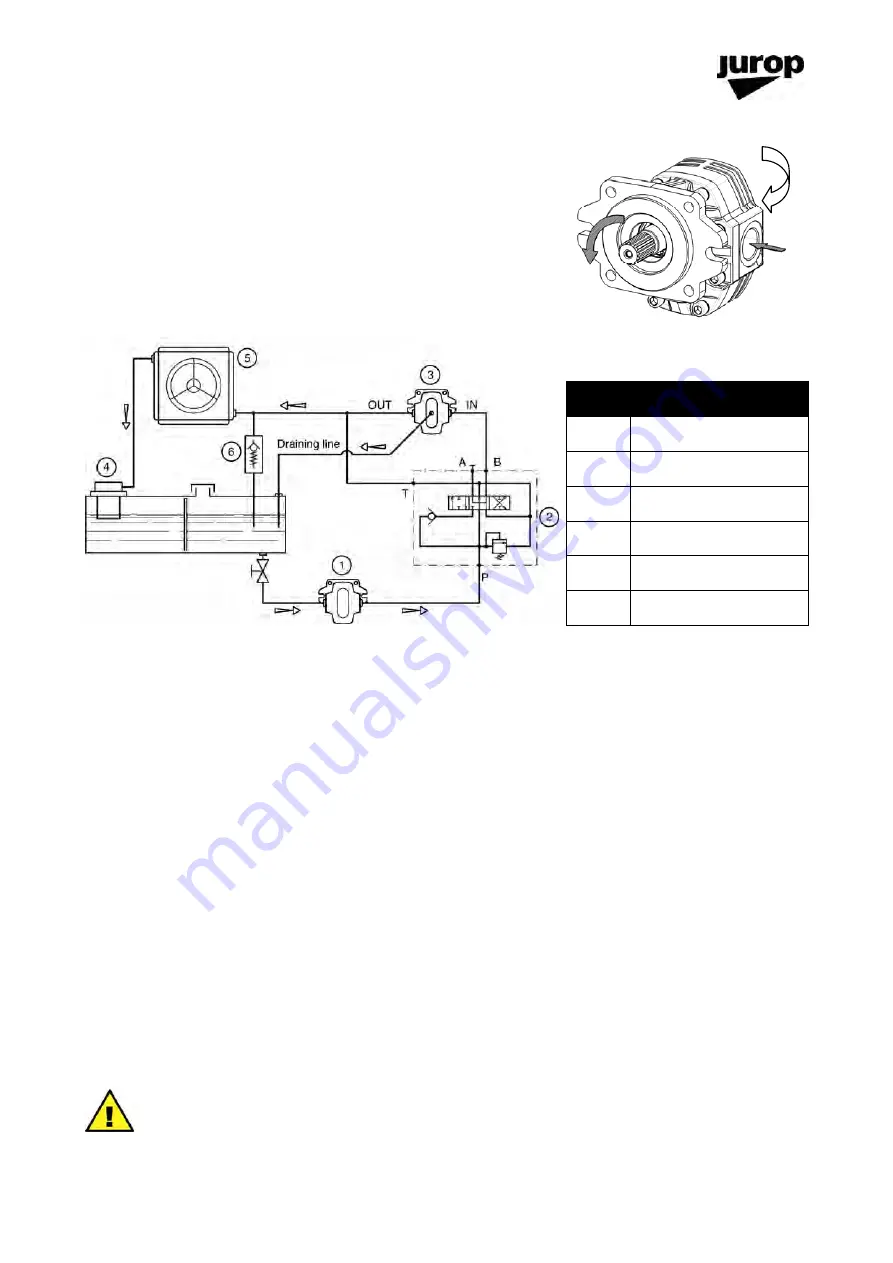

Filtration

: class 19/16 contamination according to ISO 4406

to be obtained with a ßx = 75 filter

•

Check circuit connections

: they must be applied in the same

rotation direction as that indicated by the arrow on the pump front

flange.

•

Draining

: connect directly to the tank above the maximum oil

level. Operating without draining line may damage the motor.

Pos

Description

1 Hdr

pump

2 Distributor

3 Hdr

motor

4 Oil

filter

5 *

Heat exchanger

6 *

Safety valve

* : optional components

•

Distributor

: open-centre distributor in central idle position (vacuum pump off). It must be

equipped with an adjustable overpressure safety valve.

•

Motor pipeline

: outlet pipe must not be of a smaller diameter than that of the inlet port. Inlet pipes

always have a diameter smaller than outlet pipes. Choose preferably flexible pipes to avoid

vibration transmission.

•

Tank

: with suction pipe and return separated by baffles. If necessary, use a heat exchanger to

avoid oil heating above 70-80°C and protect it from extreme pressure with a pressure relief valve.

Minimum approximate capacity: as twice as the circulation flow.

•

Starting-up

: be sure that the system is well cleaned and pour oil into the tank and into the motor

housing (necessary to

lubricate the internal bearings).

•

Vent the circuit and adjust the overpressure safety valve to the lowest possible value.

•

Check the oil tank level.

•

Increase pressure and rotation speed until operating values are reached.

PRECAUTIONS WHEN STARTING THE SYSTEM

Check oil levels in gearbox and side mounted tank.

Check that all protection devices are correctly installed.

Check that there are no obstacles in the vacuum line.

Check rotation direction: open all system valves and start running slowly.

Do not rotate in the wrong direction: this may damage the vacuum pump. Follow the arrow

indicated on the front flange.

DRAINING

PORT

www.fraserwoods.ca