REV

. 10

22-04-2020

INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

PN

19 / 40

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

. +39 0434 636811 F

AX

. +39 0434 636812

http://www.jurop.it

e-mail: [email protected]

Pos

Code

Description

1

-

VANE

2

1610006600

FLANGE

3

1610500400

FRONT OIL SEAL FLANGE

4

1610500500

FLANGE

5

1680700400

FLANGE GASKET

6

4022200110

SEAL 72X48X15

7

4022200240

O-RING 4825

8

4023100040

BEARING 6308

9

4026300020

COMPENSATION RING

10

4026305614

SELF-BLOCKING NUT M24X2

Disassemble operation

• After removing the cardan guard and the front shaft (smooth /

broached), loosen and remove the self-locking flanged nut (10) and the

direct intake transmission flange (2).

• Remove the front oil seal flange (3) and its gasket (5).

• Remove the decompressor flange (4) using the threaded holes for

removal. Do not lose the underlying O-Ring (7).

• Support the shaft before removing the flange: the weight of the

rotor must not cause any abnormal stress on the internal components.

• Remove the worn vanes (1).

• Complete the disassembly procedure:

Remove the bearing (8) and the seal rings (6) from the

decompressor flange (4);

Do not lose the compensation ring (9).

Remove the seal ring (6) from the front flange (3).

Assemble operation

• Fit the seal ring (6) on the transmission flange (4).

• Reassemble the components in the following order:

Replace the O-Ring (7) and secure using grease in the front

flange seat.

Replace the seal ring (6).

Fit the flange (4) on the body: avoid damaging the seal rings

(6) while fitting them on the shaft. Insert the bearing (8)

properly and all the way into its seat and fit the compensation

ring (9).

Replace the seal ring (6) on the flange (3) and mount on the

flange (4) replacing the gasket (5).

Direct intake transmission flange (2) and self-locking flanged

nut (10)

Smooth / broached shaft

Cardan shaft guard.

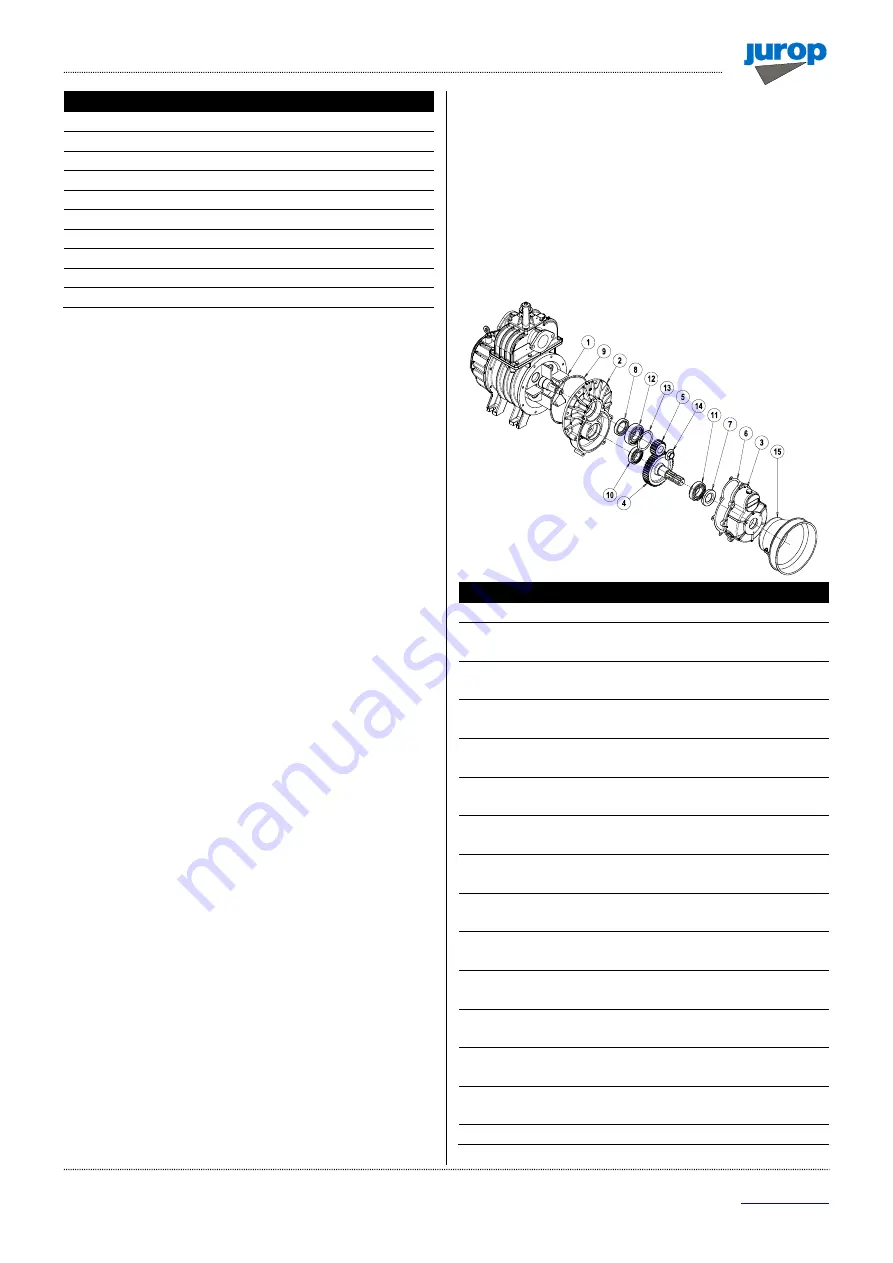

PN with Gearbox

Disassemble operation

• Remove the transmission, if any. Check its conditions.

• Remove the cardan shaft guard (15).

• Remove the gearbox (3) and relative gasket (6).

• Remove the seal ring (7) and the bearing (11) fitted on the gear

wheel (4). At the same time loosen and remove the flange nut (14).

• Remove the gear wheel (4) and pinion (5).

• Remove the decompressor flange (2) using the threaded holes for

removal. Do not lose the underlying O-Ring (9).

• Support the shaft before removing the flange: the weight of the

rotor must not cause any abnormal stress on the internal components.

• Remove the worn vanes (1).

• Complete the disassembly procedure:

Remove the bearings (10) and (12), the seal ring (8) from the

decompressor flange (2);

Do not lose the compensation ring (13) fitted in models PN 45-

58-84-106.

Pic. 6.8

Pos

Code

Description

1

-

VANE

2

1610503900

GEARBOX FLANGE PN23-33

1610500000

GEARBOX FLANGE PN45-…-106

3

1612501300

GEARBOX PN23-33

1612503100

GEARBOX PN45-…-106

4

1651000300

GEAR PN23-33

1651000000

GEAR PN45-…-106

5

1651000200

PINION PN23-33

1651000100

PINION PN45-…-106

6

1680700900

GASKET PN23-33

1680700000

GASKET PN45-…-106

7

4022200032

SEAL PN23-33

4022200040

SEAL PN45-…-106

8

4022200025

SEAL PN23-33

4022200110

SEAL PN45-…-106

9

4022200230

O-RING PN23-33

4022200240

O-RING PN45-…-106

10

4023100018

BEARING PN23-33

4023100020

BEARING PN45-…-106

11

4023100020

BEARING PN23-33

4023100130

BEARING PN45-…-106

12

4023100018

BEARING PN23-33

4023100040

BEARING PN45-…-106

13

4026510025

SEEGER PN23-33

4026300020

SEEGER PN45-…-106

14

4026305612

NUT M20X1,5

4026305614

NUT M24X2

15

4029602806

DRIVE SHAFT PROTECTION